Home \ International \ 52 cranes at Hinkley Point C work in safety thanks to the expertise of AMCS technologies

52 cranes at Hinkley Point C work in safety thanks to the expertise of AMCS technologies

05/05/2021

Pubblicato da Redazione Redazione

Since three years AMCS technologies has had the privilege of participating in one of its most challenging projects.

The company specialised in zoning and anti-collision systems for lifting machines equips the 52 tower cranes at the Hinkley Point C nuclear power plant site in England. This site benefits from all the expertise of AMCS technologies in terms of safety and productivity.

The construction of the buildings that will house the two nuclear reactors is currently being carried out by 52 tower cranes with horizontal and luffing jibs, of which 4 are traveling. They are all equipped with the DCS 61-S, the latest generation anti-collision and zoning system from AMCS technologies.

The company also supplies part of this extraordinary project with additional security products (cameras, aircraft warning lights, etc.).

This project represents a real technical challenge in the market of anti-collision, due to the high number of different kind of cranes in a very small area.

AMCS technologies has been meeting this challenge for more than 3 years by installing 52 anti-collision systems which are all in active mode today and running daily. The anti-collision system is essential to ensure the safety and productivity of this project. The 52 tower cranes each have several inference zones with other cranes. This means that several cranes can work in the same area and the risk of collisions between their cables or between cables and jibs could occur.

The DCS 61-S systems allow these numerous areas of interference to be managed in real time. Consequently, this ensures the productivity of the site but also the safety of the machines and the 3,500 workers (in periods of high traffic) mobilized day and night (20 hours per day), 7 days a week. The DCS 61-S detects in real time the risk of collision of all interfering crane components (for example jib on jib, jib on cable, etc.). The device calculates in real time and in 3D the distances between each element of the cranes as well as the speeds and direction of movement (when they are on the rails) in order to intervene on the control mechanisms of the crane to ensure a slowing down and then a complete immobilization of the machine at a preset distance from the other machine.

The system also provides the crane operator with working comfort by displaying all the parameters useful for operating the machine. It gives him the possibility of visualizing in real time the position of his crane as well as the positions of interfering cranes as such guaranteeing high performance in terms of site productivity. AMCS technologies also developed site supervisors (SUP 61) available for site management. They can view and monitor in real time the activity of the cranes as well as their positions, the operation of the DCS 61-S devices installed on the site and all other useful information (eg wind speed).

Ultime notizie di AMCS Technologies

30/08/2021

AMCS equips the new construction site of Scandinavia's largest hospital "Universitetssykehus Radiumhospitalet"

The four COMANSA cranes on the site are equipped with DCS 60...

12/07/2021

AMCS Technologies: safety in Paris!

AMCS Technologies ensures work safety for the Paris Grand Ex...

22/12/2020

The 18 cranes at the Fécamp wind farm site will be equipped with the DCS 61-S anti-collision system from AMCS technologies

The 18 Potain tower cranes that make up the foundation site...

20/10/2020

AMCS technologies manage the anti-collision between tower and mobile cranes

AMCS technologies unveils its anti-collision solution betwee...

05/10/2020

Another "Grand Paris Express" project equipped with DCS 61-S

Five Wolff 7534.16 as well as three MDT 308 have been erecte...

07/09/2020

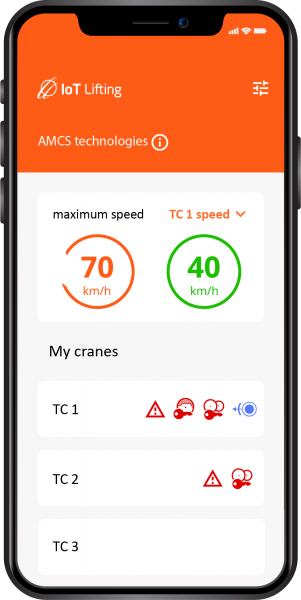

AMCS technologies’ IoT lifting web and mobile application solution is available

Monitoring your site's productivity with precision and...

Altri International

International

19/04/2024

Hitachi presents specially adapted ZX390TC-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will displ...

International

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

International

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

International

18/04/2024

JCB: Stage V Powertrain for large platform Skid Steer Loaders

JCB has launched EU Stage V compliant versions of its large...

International

17/04/2024

Color change signals bold new era at Yanmar CE

Yanmar Compact Equipment is undergoing a shift in its approa...

International

17/04/2024

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...