Home \ International \ Danish construction company M.J. Eriksson relies on Liebherr TA 230 Litronic dump truck

Danish construction company M.J. Eriksson relies on Liebherr TA 230 Litronic dump truck

24/03/2022

Pubblicato da Redazione

– Danish construction company M.J. Eriksson A/S opted for an articulated dump truck TA 230 from Liebherr.

M.J. Eriksson A/S is one of Denmark's largest construction companies and specialises in general civil engineering, special civil engineering and track construction work. The company has the most advanced and largest machine fleet in the country. Over half of the machines are from Liebherr.

The TA 230 articulated dump truck has been proving its worth at Eriksson since 2021 and is used successfully in various road construction projects in Denmark and southern Sweden. It is responsible for the movement of materials in remediation work of existing infrastructures or the creation of new infrastructures.

Eriksson is impressed by the overall concept of the TA 230: The machine moves up to 28 tonnes of material per loading. A powerful drive train combined with the automatic traction control give the machine excellent driving performance and combined traction. This increases the operating efficiency and ensures higher handling capacity as well as greater cycle times on the construction sites. The company uses the TA 230 at different locations with a radius of up to 500 kilometres. Another advantage of the Liebherr dump truck is demonstrated here: Thanks to the optimal transport width of under three metres, it can be transported quickly and without a costly special permit. The machine also meets customer expectations in terms of comfort and design, which was another decisive factor in the decision-making process.

"In Denmark and southern Sweden the soil conditions are often sandy and loamy", says Jørgen Eriksson, Managing Director and owner of the company, describing the operating conditions on site. "A major discipline for the TA 230. Even in the most difficult soil conditions and on inclines, the machine displays enormous traction, even when fully loaded. Better than all the other machines in our fleet", he adds. This is down to the optimal combination of a powerful engine, efficient drive train and maximum traction. A 6-cylinder construction machinery engine with 12 litre capacity and 265 kW / 360 hp does its job under the bonnet. This ensures the excellent driving performance. At full speed the machine reaches top speeds of up to 57 km/h and 16 km/h in reverse. The efficient drive train comprises an automatic 8-speed powershift transmission and is responsible for the optimal power transmission. The 6 x 6 permanent all-wheel drive and the powershift longitudinal and transverse differential locks give the dump truck continuous traction. Due to the prevailing soil conditions Eriksson opted for wide base tyres which increase ground contact and ensure that the machine sinks less.

Martin Eriksson, Project Manager at M.J. Eriksson A/S, praises the machine’s high level of comfort: "Liebherr managed to optimally integrate driver comfort and technical drive comfort. Our machine operators are impressed with the generously dimensioned cab with the modern space design as well as the drive comfort." The cab is accessible in a safe and easy manner thanks to the offset steps and the large driver's door. Various storage areas, one of which is air-conditioned, as well as bottle holders, extend the available space. The clearly and intuitively arranged operating elements facilitate the work of the machine operators who are quickly ready for the shift. Shock absorbers on the front axle as well as the viscoelastic bearing at the cab optimally absorb the vibrations occurring during use. The soundproof cab also reduces the noise level in the cab to a mere 72 dB(A). This enables long, fatigue-free shifts. The machine has room and space for productive, comfortable work.

Large infrastructure projects often involve several individuals and construction machines with work carried out from morning till night. As such the safety requirements of the machines are high. Here Eriksson sees clear advantages in the lighting concept and visibility from the Liebherr dump truck. The driver's cab features excellent panoramic windows without any obstructing struts. A short, inclined bonnet gives the machine driver an optimal view of the driving, working and articulated joint area of the machine. A rear-view camera is integrated in the touch display, whereby the rear machine area is visible. LED dipped-beam headlamps with integrated main beam and extra strong LED headlamps on the front of the cab illuminate the route and work area. "The innovative lighting concept creates optimal conditions for working in the dark. At the same time it ensures that the machine is always visible to all individuals on site", concludes Martin Eriksson.

The lighting concept is also part of the new machine design with edgy and dynamic styling. Jørgen Eriksson was impressed by the visual appearance of the TA 230 from the beginning: "It is a true highlight in our fleet."

Liebherr, the sales and service partner Johs. Møllers Maskiner A/S and M.J. Eriksson A/S have been working as partners for many years. Uwe Kulik, General Manager Key Account at Liebherr-Export AG, looks back: "For over 40 years Eriksson has placed its trust in our powerful and high-quality machines." Leif Petersen, Managing Director of Johs. Møllers Maskiner A/S is delighted that Jørgen Eriksson describes the competent service of Johs. Møllers Maskiner A/S as "the best in Denmark": "A compliment that makes us very proud."

M.J. Eriksson A/S is one of Denmark's largest construction companies and was set up in 1945. The range of services is comprehensive and includes general civil engineering and special civil engineering work and track construction. The family-run company is now managed in the second generation by Jørgen Eriksson and employs around 700 staff at eight different locations in Denmark and Sweden. Since 2015 the company has generated over 2 billion Danish kroner each year.

Ultime notizie di Liebherr EM-Tec Italia

Earthmoving Machinery

16/04/2024

Used Equipment Marketplace: New portal for Liebherr used machines

– Digital marketplace with an extensive portfolio of used ma...

Perforation

04/04/2024

LRB 23 continues the success story of piling and drilling rigs for Liebherr

The piling and drilling rig type LRB 23 closes the gap betwe...

Earthmoving Machinery

27/03/2024

Liebherr-Werk Bischofshofen invests in a new assembly hall

Separate hall for the assembly of the L 507 E battery-electr...

Earthmoving Machinery

25/03/2024

New carrier machine for slurry wall construction Liebherr LBX 600

Liebherr launches a new carrier machine for slurry wall cons...

Earthmoving Machinery

22/03/2024

Liebherr mixing tower supplies quality concrete for crane ballast weights

– Högerle Betonwerk GmbH has put a new Betomat mixing tower...

Earthmoving Machinery

14/03/2024

The Liebherr R 980 SME in slag handling operations

This R 980 SME crawler excavator was specifically designed f...

Altri International

International

19/04/2024

Hitachi presents specially adapted ZX390TC-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will displ...

International

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

International

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

International

18/04/2024

JCB: Stage V Powertrain for large platform Skid Steer Loaders

JCB has launched EU Stage V compliant versions of its large...

International

17/04/2024

Color change signals bold new era at Yanmar CE

Yanmar Compact Equipment is undergoing a shift in its approa...

International

17/04/2024

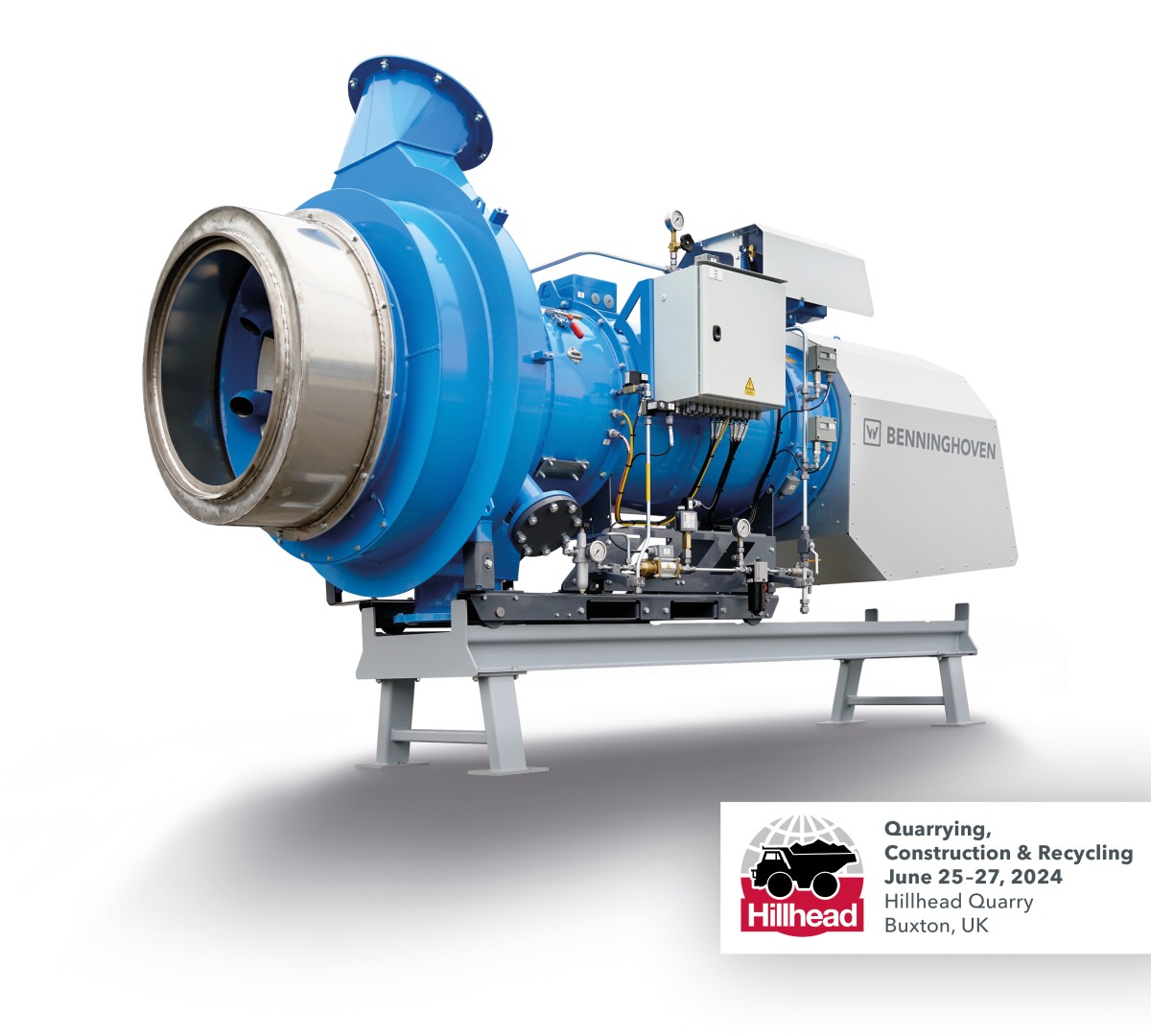

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...