Home \ International \ Epiroc at Bauma 2019

Epiroc at Bauma 2019

11/03/2019

Pubblicato da Redazione

Epiroc, a leading productivity partner for the mining, infrastructure and natural resources industries, presents a new set of innovative and productive offers at Bauma.

Epiroc, a leading productivity partner for the mining, infrastructure and natural resources industries, presents a new set of innovative and productive offers at Bauma. Updated and new products that will help customers meet the demands of the future – all while saving time and money.

Helena Hedblom, Senior Executive Vice President Mining and Infrastructure: “Our journey as Epiroc started in 2018 when the mining and part of the infrastructure business spun off from Atlas Copco and became an independent company. As a 145-year-old startup we have the opportunity to think fresh. Combined with our clear focus and great passion for our industries we’ve been able to rapidly grow into the minds of our customers and beyond. Bauma is an ideal opportunity for us to meet and develop an even closer relationship with our customers in construction, while showcasing our strong offer and focus to the market.”

Demolition, recycling and rock excavation with hydraulic attachment tools

Longer service life, great flexibility and higher carrier utilization have been the essential fields of development for Epiroc´s hydraulic attachment tool designers recently. Epiroc expands the offering by smart additions that save customer´s investments, increase their productivity and carry out their work in the best possible way.

Pulverizer jaws for Combi Cutters

Epiroc introduces Pulverizer jaws for the CC 3100 Combi Cutter at Bauma, more models will follow during Q2 2019. Pulverizer jaws offer more applications with one cutter body, the utilization of the cutter is increased and rounds off the needs on smaller jobsites. Epiroc´s Coupling and Positioning System (CAPS) makes it easy to switch between the jaw types on site to suit the work at hand. The full jaw range consists of Universal (U) jaws, Steel Cutting (S) jaws and Pulverizer (P) jaws.

New Combi Cutter CC 1600

The new CC 1600 Combi Cutter model is designed for carriers in the 13-23 ton class. The stable cutter body features two powerful hydraulic cylinders with integrated speed valves for minimum cycle times and, in turn, minimum fuel consumption. Fully protected by piston rod guards, the cylinders deliver virtually constant closing force which remains high even when the jaws are almost closed. Two jaws moving independently eliminate displacement forces on the cutter and the carrier, ensuring controlled demolition of unstable concrete walls, regardless of which jaw attacks the material first.

Updated Multi Grapple range

By redesigning the MG multi grapple range to make it even more robust, we’re able to meet the increasing demands form customers even more, who face tougher jobsite conditions and higher utilization of grapples in their day-to-day work. The MG 1000 will be on display at Bauma and the entire range will be replaced step by step during Q2 and Q3. As a new option, to allow even better customization of the grapples, they can now be ordered with or without rotation device, to enable operation of the base units in combination with tiltrotators.

Transverse drum cutters with cutting wheel option

The new cutting wheel option is available for our ER/ERC 50 – ER/ERC 3000 transverse drum cutters. Precision is key when it comes to cutting narrow trenches for cables or pipes. Now trenches with a width of 55 - 250mm and a depth ranging from 150 mm (ER/ERC 50) up to 700 mm (ER/ERC 3000) can be cut in one go.

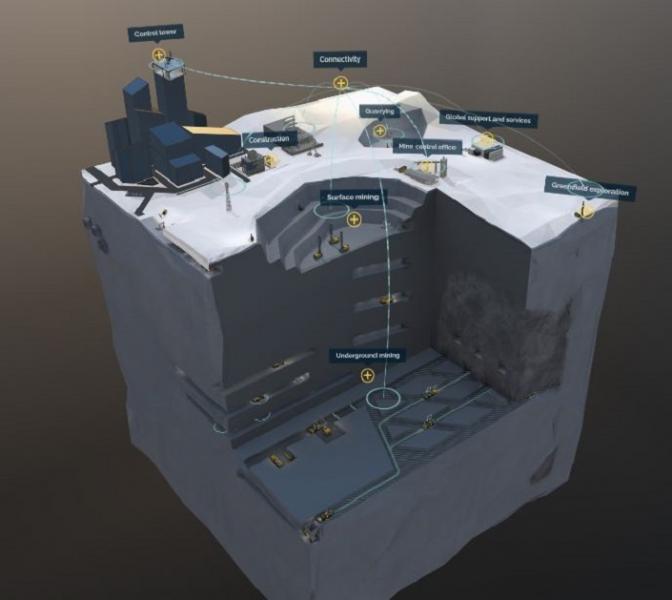

The latest in smart surface and underground mining at Bauma

Helena Hedblom: “Making mining smarter and keeping our customers at the forefront of development sits at the very heart of our business. We constantly push ourselves in areas such as digital automation and interoperability, connected products and integrated systems. Clever and high-quality solutions that increase safety and sustainability. In close collaboration with customers and other stakeholders of the industry we bring ideas to actual products. And we’re very happy to present the latest ones here at Bauma.”

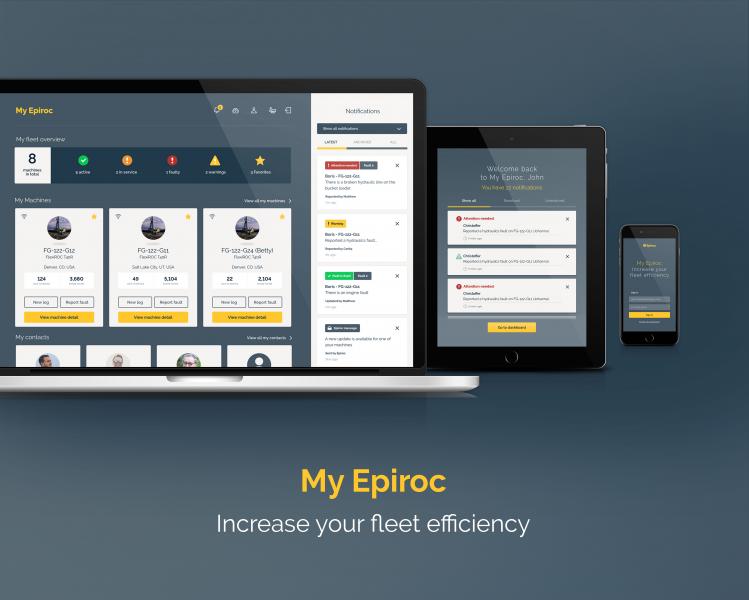

Increase your fleet efficiency with My Epiroc

My Epiroc is a new total solution for the mining and infrastructure industry, a platform available on web and mobile devices with attractive new features for increasing fleet efficiency and safety. Whether you are a fleet manager focusing on uptime, an operator getting the job done out in the field, or a member of the service department staying on top of fleet performance, My Epiroc is made for you – to get your work done with speed and efficiency. So that you can focus on what’s important.

Surface and Exploration Drilling

The Surface and Exploration Drilling division will launch a new mining rig platform – a future-proof surface drill rig featuring our latest technology such as Auto FeedFold and improved fuel efficiency. More information will be revealed in the next quarter. Follow our social media channels and visit Epiroc.com to stay updated.

Optimal air quality with Serpent Automatic

Serpent Automatic is a smart, automatic solution that guarantees optimal air quality for a safer and healthier underground work environment. Epiroc now introduces several new upgrades which will help customers keep control over air quality and optimize running costs. Some of the new features include: vibration control, a safety feature avoiding risk for vibrations that can harm the fan station, master-slave function to operate a

series of fans in a more secure way and active pressure- and flow measurement which gives actual performance data helping the user to foresee any future risks with bad air quality due to bad installation or air leakages. At Bauma we are now launching the integration between Serpent Ventilation and Mobilaris MMI, which helps to increase safety and health for operators and improves energy efficiency for an underground tunnel or mine site. Mobilaris MMI can monitor ventilation components and installation as well as control the airflow based on sensor monitoring. In case of deviation, alarm will be visible in Mobilaris MMI.

Grouting made easier

Unigrout Flex, the ultimate ground treatment method to seal mines and tunnels, or to improve ground properties, will be on display at Bauma. With an improved option list and different stand-alone products, Epiroc now offers monitoring, controlling and utilization of the latest and greatest chemicals used in grouting, helping customers to increase productivity with external hardener injection and multihole grouting.

Next level precision spraying

The mobile and cost-effective concrete sprayer MEYCO ME5 is the ideal choice for civil tunneling projects with mid- to large openings. Thanks to the MEYCO Dosa system, customers get a highly accurate and flexible dosing adjustment that is always right on target. At Bauma, Epiroc will show several new upgrades to the ME5. Improvements that will help save money on reduced material costs.

Safety and productivity with mechanized pipe roofing

Epiroc launches a mechanized pipe roofing system, showcased at Bauma on the hydraulic face drill rig Boomer E2. The mechanized system is a major safety benefit, which eliminates manual handling of drill rods and umbrella pipes as it remotely controls the adding and retracing of pipes and rods from the service platform. By reducing manual work, safety is increased. The mechanical system also ensures improved productivity. With a great overview from the service platform, close to the actual work, the pipe roofing system will benefit the whole operation.

Leading the way to zero-emission

Epiroc leads the change towards sustainability in mining through battery electric, zero-emission equipment. The result is a safer and healthier underground working environment. After more than 60 000 operating hours, we have expanded our proven battery offering and zero-emission underground fleet with the second generation in rigs for face drilling, production drilling and rock reinforcement, loaders and mine trucks. Join us at Bauma to learn more about our zero-emission offering. A power change – that changes everything.

Mining intelligence

Mobilaris is a position-based decision support system that increases personnel safety and productivity. It can be used to track and find equipment, vehicles, personnel and oversee infrastructure in real-time 3D. Thanks to its open interface Mobilaris is also easy to integrate with other mining applications.

Additional flexibility for DM series drill rig with Epiroc’s Rig Control System (RCS) Lite.

Epiroc has increased the technology capabilities of its DM series of drills with RCS Lite. The new version of the successful Rig Control System (RCS) boosts efficiency and productivity of models such as the DM30 II, DM45, DML, DM-75 and DM-M3 with three levels of software and hardware systems that will give the popular and long-running line of blasthole drilling rigs capabilities.

Powerbit Underground

The new Powerbit Underground drill bit range makes tophammer drilling faster than ever. Made of our hardest steel ever and featuring innovative button technology, Powerbit Underground offers a supreme penetration rate and many more meters before the first grind.

New improved COPROD head and bits

Epiroc introduces new COPROD head- and bit technology. The developments include a complete range of Powerbit drill bits, and a more effective head with fewer parts. For drillers, this means easier handling, better hole quality, increased penetration rates, lower fuel consumption and greatly improved productivity.

COP M6, COP M7 and COP M8 down-the-hole hammers

Epiroc launches a new series of down-the-hole hammers – COP M6, COP M7 and COP M8. Based on an upgraded technology concept, these hammers will allow miners to drill larger holes without the need for a larger rig. By simply replacing a few internal components, these hammers can also be adapted for use on different types of rigs.

New digital solutions bring life to consumables

Epiroc launches its “A bit smarter” concept, a set of digital solutions that turn consumables into smart, connected components using customer data and the latest wireless technologies. Check out Smart Consignment and Product Identification at Bauma.

Ultime notizie di Epiroc Italia

Equipments

21/12/2023

Epiroc to acquire Stanley Infrastructure from Stanley Black & Decker

Epiroc to acquire Stanley Infrastructure from Stanley Black...

Perforation

11/04/2023

Epiroc partners with ispace for Moon missions

Epiroc has signed a long-term collaboration agreement with i...

Perforation

01/08/2022

First ever battery-electric surface drill rig field tested in Swedish quarry

Epiroc has entered an agreement with Skanska Industrial Solu...

11/11/2020

New "World of Epiroc" online feature highlights ground-breaking customer solutions

Epiroc, a leading productivity partner for the mining and in...

13/02/2020

Epiroc Italia at SaMoTer 2020!

Epiroc will display at SaMoTer the range of hydraulic attach...

02/12/2019

Helena Hedblom appointed Epiroc’s next President and CEO

The Board of Directors of Epiroc AB has appointed Helena Hed...

Altri International

International

26/04/2024

Digitalisation and sustainability at the Wirtgen Group's "Technology Days"

Digitalisation and sustainability were the focal points of t...

International

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...

International

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

International

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

International

24/04/2024

New Palfinger's TEC Heavy-Duty Cranes Set Standards in Power & Precision

The new Palfinger PK 1350 TEC and PK 1650 TEC heavy-duty cra...

International

24/04/2024

SSAB and Manitou Group agree on fossil-free steel

Manitou Group announces the signature of a letter of intent...