Home \ International \ First Benninghoven's Recycling Priority Plant (RPP) begins asphalt production in Switzerland

First Benninghoven's Recycling Priority Plant (RPP) begins asphalt production in Switzerland

06/06/2023

Pubblicato da Ettore Zanatta

The asphalt mixing plant with hot gas generator technology begins production after a construction time of only six months

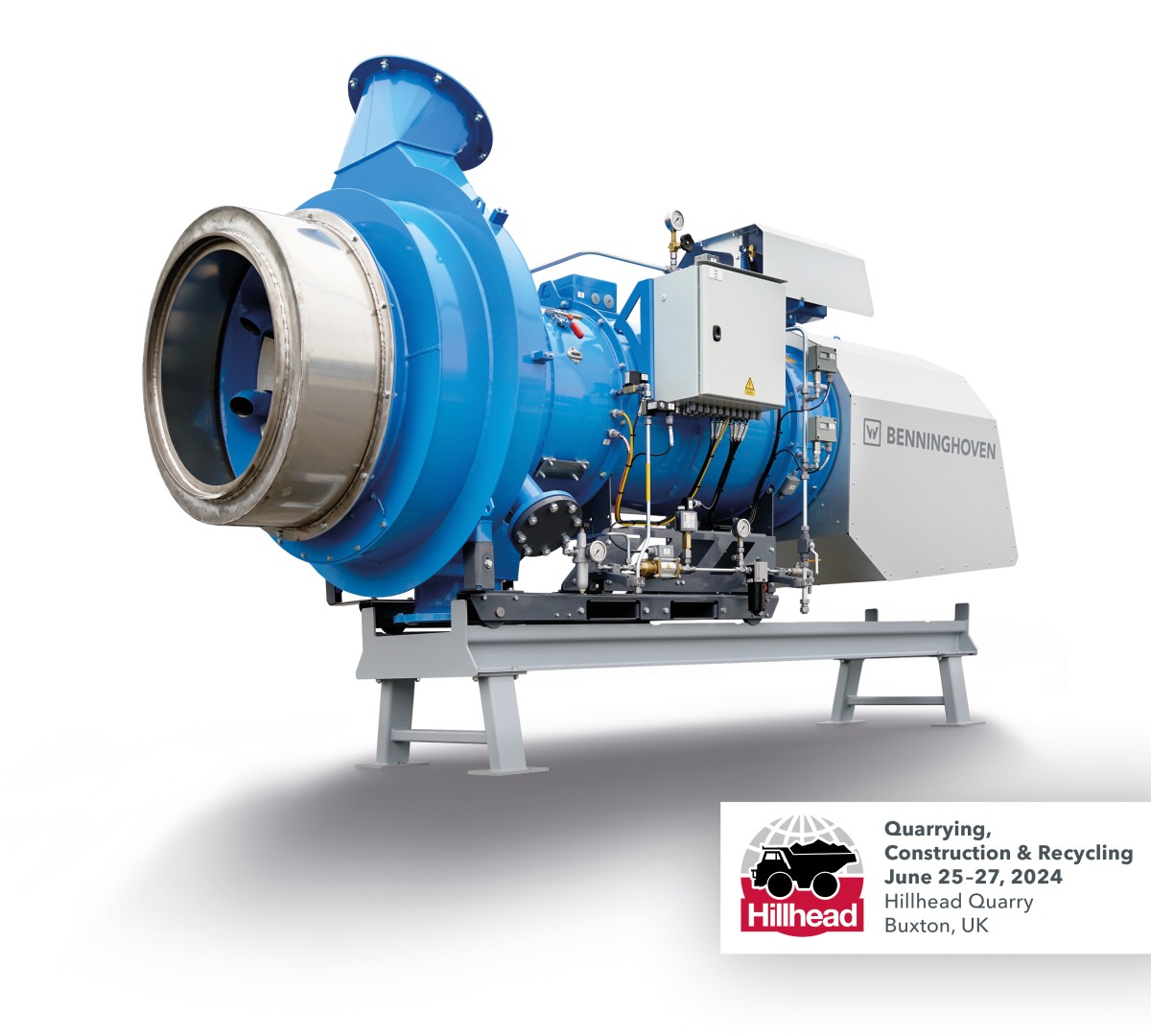

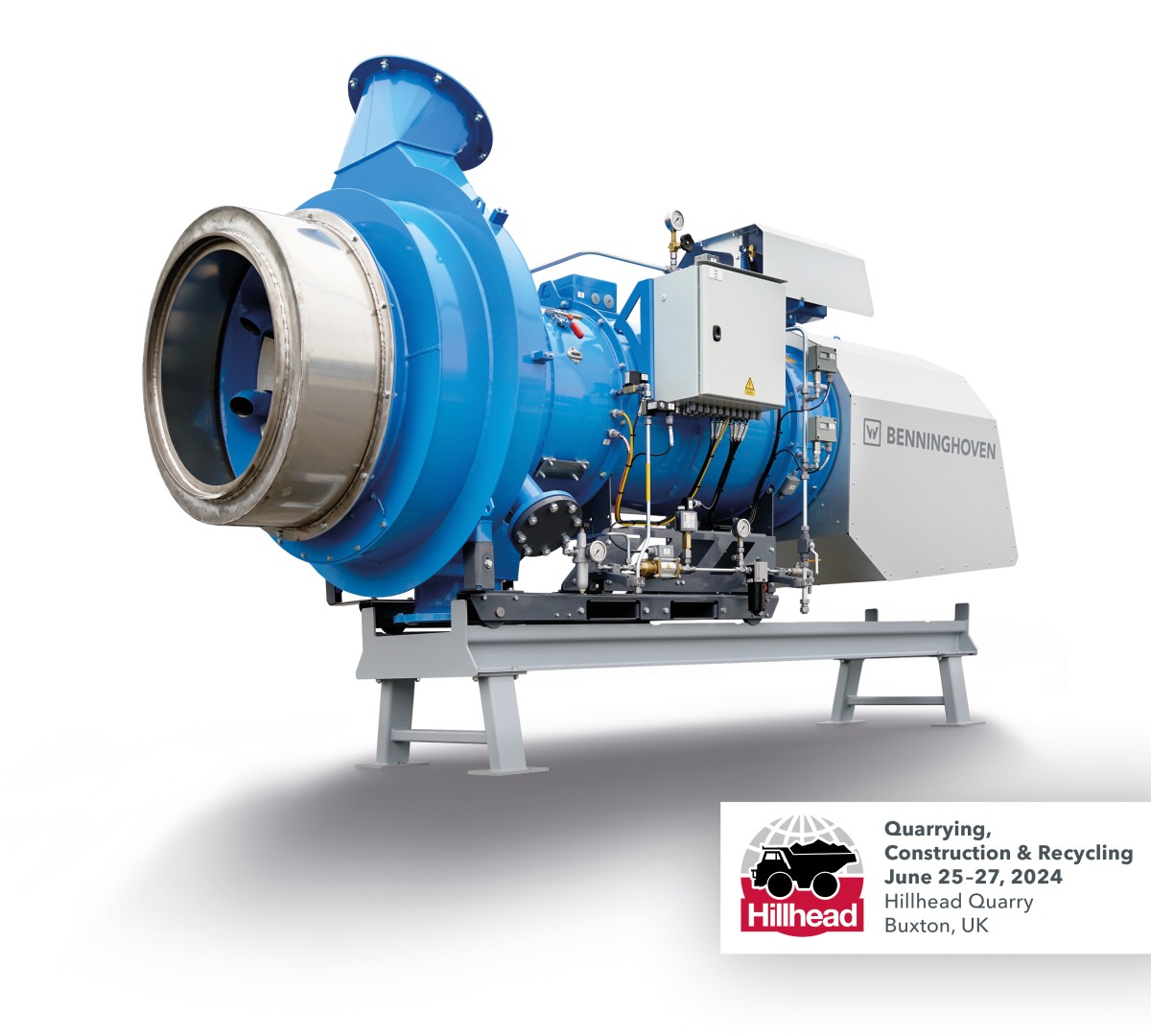

The new Benninghoven RPP 3000 Plus (RPP = Recycling Priority Plant) is the first asphalt mixing plant in Switzerland to be equipped with environmentally friendly hot gas generator technology. Above all, the plant impressed the customer with high recycling rates, low emission values and clearly defined quality standards.

As a subsidiary of Implenia, Switzerland’s biggest construction company, SAPA (Societe Anonyme De Produits Asphaltiques) supplies its customers with asphalt mixes of all kinds, mainly for smaller and medium-scale road construction projects. For the Swiss, sustainability and energy-efficiency are high-priority issues. This was also one of the reasons why the owners decided to replace the existing plant in Satigny, not far from Geneva, with a new, next-generation asphalt mixing plant. As Benninghoven asphalt mixing plants set technological benchmark standards in this respect, and in view of ever tighter environmental regulations and increasing demands on asphalt mixing plant operators to realise higher RAP feed rates, they are also a particularly cost-efficient and sustainable solution.

On average, asphalt mixing plants in Switzerland produce 60,000–80,000 t of material per year; that’s up to 40,000 t less than the quantities produced in other countries. Regulations with regard to recycling, sustainability, conservation of resources, and carbon emissions are nevertheless the same as in the rest of Europe. Asphalt mixing plants must produce qualitatively flawless mix with minimal environmental impact and set their focus on the recycling of the material – and that at every output level. In this project, a minimum proportion of RAP > 60 % was one of the highest priorities on the list. A figure that the RPP 3000 Plus can easily top, as RAP feed rates of up to 100 % are no problem at all for an RPP-type asphalt mixing plant with hot gas generator technology.

After the customer had defined the project requirements, Benninghoven developed a concept for a plant of the required size with an end of service life horizon of 30 years. The RPP 3000 Plus proved to be the ideal solution, not least thanks to its high efficiency and cost-effectiveness, new cycling technologies and the local service infrastructure and rapid availability of service technicians and spare parts. As soon as the decision was made, progress began at a rapid pace. The entire process, from plant construction to commissioning, took only six months.

In order to fulfil the requirements of the Swiss Revised CO₂ Act and the Ordinance on Air Pollution Control (OAPC) in every respect, the customer aims to use the new plant to reduce CO₂ emissions through the proportion of RAP and the fuels employed and achieve a significant reduction of the overall carbon emissions (Cges) by the use of hot gas generator technology. The use of a recycling drum with a hot gas generator enables compliance not only with currently applicable threshold values, but also those of even more stringent future legal requirements.

Switzerland is targeting a reduction of greenhouse gas emissions by one-half by 2030. In order to achieve this target, the new CO₂ Act focuses on investments in climate protection and advanced technologies, and combines these measures with financial incentives. In addition to prescribing emission limits, the new OAPC also requires asphalt mixing plants to fulfil specific constructional and operational requirements, e.g. continuous temperature monitoring of the mineral aggregates and asphalt granulates in the recycling drum. These criteria were also taken into account in the case of the RPP 3000 Plus asphalt mixing plant in Satigny, where this example of the latest generation of Benninghoven asphalt mixing plants is now producing asphalt for Swiss roads and motorways with minimal environmental impact and maximum efficiency.

Ultime notizie di Wirtgen Macchine

Earthmoving Machinery

17/04/2024

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...

Earthmoving Machinery

16/04/2024

Kleemann's SPECTIVE CONNECT: now new with Tool Management

The intuitive SPECTIVE operating concept makes a significant...

Road Machinery

11/04/2024

Vögele: Spectacular road construction project in the Himalayas

Two Vögele pavers involved in the construction of the Zoji-L...

Road Machinery

03/04/2024

Wirtgen Group cold recycling: from dusk to dawn!

A cold recycling train from the Wirtgen Group completes the...

Earthmoving Machinery

26/03/2024

Three new mobile impact crushers in southern France

Three impact Kleeman crushers with double-deck post screenin...

Road Machinery

05/03/2024

The Wirtgen Group Brings a World Premiere to World of Asphalt 2024

The Compact Milling Machine W 150 Fi Leads the Field of Sust...

Altri International

International

19/04/2024

Hitachi presents specially adapted ZX390TC-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will displ...

International

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

International

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

International

18/04/2024

JCB: Stage V Powertrain for large platform Skid Steer Loaders

JCB has launched EU Stage V compliant versions of its large...

International

17/04/2024

Color change signals bold new era at Yanmar CE

Yanmar Compact Equipment is undergoing a shift in its approa...

International

17/04/2024

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...