Home \ International \ German contractor completes complex landscape design with Trimble technology

German contractor completes complex landscape design with Trimble technology

02/08/2018

Pubblicato da Redazione Redazione

Franz Darger Garten- und Landschaftsbau completes a Libeskind construction and landscaping project, from earthmoving to paving, more quickly and with less rework with the Trimble GCS900 Grade Control System and a Trimble Universal Total Station

Customer Profile: Franz Darger Garten- und Landschaftsbau is a modern, family-run gardening and landscaping company that operates in Germany in the areas of Lüneburg, Hamburg and Schleswig-Holstein. The company offers services for housing associations as well as public and private sector clients.

Business Challenge: The project was to complete all earthmoving, designing and paving work around a prominent new building at Leuphana University designed by the celebrated architect Daniel Libeskind, whose buildings range from the Denver Art Museum to the Grand Canal Theatre in Dublin. Faced with extremely tight design specifications and a challenging work area with no GNSS reception, Franz Darger Garten- und Landschaftsbau turned to Trimble and SITECH® Deutschland for help.

Solution: Trimble GCS900 Grade Control System, Trimble SPS985 GNSS Smart Antenna, Trimble SPS930 Universal Total Station, Trimble SCS900 Site Controller Software

Benefits: grading productivity across the job increased dramatically and reduced rework to almost zero; met complex design requirements and tolerances for earthmoving, asphalt work and laying stone pavers; quick conversion of the excavator system from dual GNSS to Universal Total Station operation mode when no GNSS reception was available; improved information flow between the jobsite and office allowed for precise progress tracking and greater transparency in project billing.

Franz Darger Garten- und Landschaftsbau, based in Rullstorf Germany, was recently hired to complete the full exterior work, including all landscaping, tree planting, walkways and stone work for the newly-constructed main building at Leuphana University. Leuphana University was founded in 1946 and is in Lüneburg, Lower Saxony, Germany. The university’s new building was designed by the world-renowned Polish-American architect Daniel Libeskind. Libeskind’s work is highly-regarded and spans the globe. In 2003, Studio Libeskind’s design, “Memory Foundations,” was also selected by the Lower Manhattan Development Corporation (LMDC) as the master plan to develop the 16 acres in Lower Manhattan destroyed by the terrorist attack of 9/11.

Leuphana University’s main building is unique in that from the outside, it includes a brilliant silver-metal zinc facade that runs 37 meters high. It also includes angled walls that project boldly skywards, as well as the use of different alignments, materials and elevations. Officially completed in March of 2017, the bold design reflects optimism and progress and is a new, proud symbol of Leuphana University. Against the backdrop of this distinctively built structure, Leuphana University leaders carefully selected Franz Darger Garten- und Landschaftsbau to develop an outdoor landscape plan that would properly complement the building.

To meet the university’s exacting design specifications, Franz Darger Garten- und Landschaftsbau made the decision to leverage the Trimble and the Trimble GCS900 Grade Control System. The family-owned landscape company worked with SITECH Deutschland GmbH, the exclusive distribution partner for Trimble’s civil and engineering construction product portfolio in Germany, to install and deploy the technology solutions.

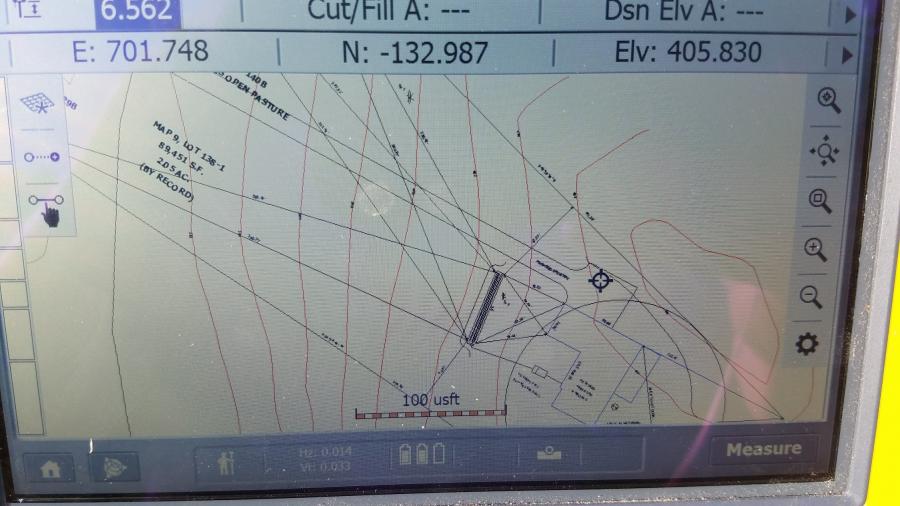

The team used the GNSS receiver to map the original terrain with high precision and to carry out further calculations on-site. The use of all available GNSS signals guaranteed efficient and productive work. When used as a rover, the SPS985 delivers a variety of site measurement tasks, such as grade checking or progress monitoring. As a GNSS base station, the SPS985 can establish a radio or Wi-Fi connection and transmit RTK corrections to another rover or to machine control systems. The team used the receiver for setting out and to collect the original ground surface, which was used to build the 3D model of the landscape plan. The Trimble GCS900 Dual GPS system then leverages the site plan - design surfaces, grades and alignments - inside the cab to grade accordingly to design.

Instead of pounding grade stakes across the jobsite, the machine control system measures the exact position, very accurate cross slope, and heading of the blade or bucket. The display in the cab shows the operator the current position, together with the target depth and inclination. The on-board computer uses this position information, and compares it to the design elevation to compute cut or fill to grade. The cut/fill data is also used to drive the valves for automatic blade control. By using an additional laser receiver, the excavator worked in both 2D and 3D modes.

Due to the position and unique design of the university building, there was one area that was particularly challenging. The building’s large overhang created a massive shaded area directly in front of the building, which blocked GNSS reception. To get around this, the company’s excavator changed from Dual GNSS to Universal Total Station operation mode. Using Universal Total Station, not only can the excavator be controlled, but it is also suitable for ultra-accurate site surveying.

The Trimble SPS930 Universal Total Station provides accurate position data to the machine control system 20 times per second. Combined with the fixed low latency and active target on the machine, the system guarantees the most precise positioning of the bucket. Using the system, the team excavated to correct depths more quickly and accurately. Together, these features impressed the managers at Franz Darger Garten- und Landschaftbau in every aspect. Team leader, engineer and master road builder Henrik Darger was particularly impressed by the high level of flexibility and accuracy achievable at all times on site with the Trimble system. He also liked that machine control and site positioning systems improve efficiency and help operators avoid expensive rework.

"We had digital 3D models of the terrain for the site, and were able to work effectively in any location,” said Darger. "Before starting our operations, we had accurate measurements of the terrain, and we were able to clarify all key questions in advance, and therefore set to work immediately on site.”

In addition, the Trimble systems allowed for real-time data sharing, including 3D digital terrain models and productivity reports, between the office and construction site. Project leaders believe this secure sharing of project data helped improve communication, project transparency and project billing. All those involved could accurately and directly trace every step on the construction site. SITECH Deutschland was also instrumental in providing reliable project support, site setup and troubleshooting help.

"A plus point that is not to be underestimated, for us, is the simple and intuitive operability of Trimble systems, which means that all users were able to operate the various systems on site without difficulty," explains Darger. “We had a smooth and easy start using machine control thanks to SITECH Germany's "try and buy" offer”. Franz Darger Garten- und Landschaftsbau was able to try out the Trimble products with no initial obligation, and become convinced of the benefits by using them before making the final investment decision.

Ultime notizie di Trimble

28/02/2019

Trimble to showcase connected construction at Bauma 2019

Trimble to Showcase Connected Construction at bauma 2019

06/08/2018

Summit Constructors builds with Trimble 3D Machine Control

Nashville-based contractor SUMMIT Constructors improves grad...

23/07/2018

Faster and more accurate excavation with Trimble in Ohio

Leading earthworks contractor tests Trimble’s new mach...

17/07/2018

"Dirt Ninja" small contractor finds big dividends with machine control

Small site contractor uses Trimble Site Positioning Systems...

Altri International

International

19/04/2024

Hitachi presents specially adapted ZX390TC-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will displ...

International

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

International

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

International

18/04/2024

JCB: Stage V Powertrain for large platform Skid Steer Loaders

JCB has launched EU Stage V compliant versions of its large...

International

17/04/2024

Color change signals bold new era at Yanmar CE

Yanmar Compact Equipment is undergoing a shift in its approa...

International

17/04/2024

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...