Home \ International \ Keestrack shifts via e-drive to ZERO drive

Keestrack shifts via e-drive to ZERO drive

15/11/2022

Pubblicato da Redazione

Keestrack presented at EIMA 2022 a 100% battery driven tractor together with technological partner Rigitrac.

In a historical period of great climatic and energy change, all industries must dedicate a strong commitment to sustainability. All manufacturing industries and their supply chains have been investing for years in finding solutions in line with the needs of times (by Research and Development). Today the technology is mature (but continues evolving) to “drive” off-highway machinery which is capable to produce with zero carbon emission to the environment.

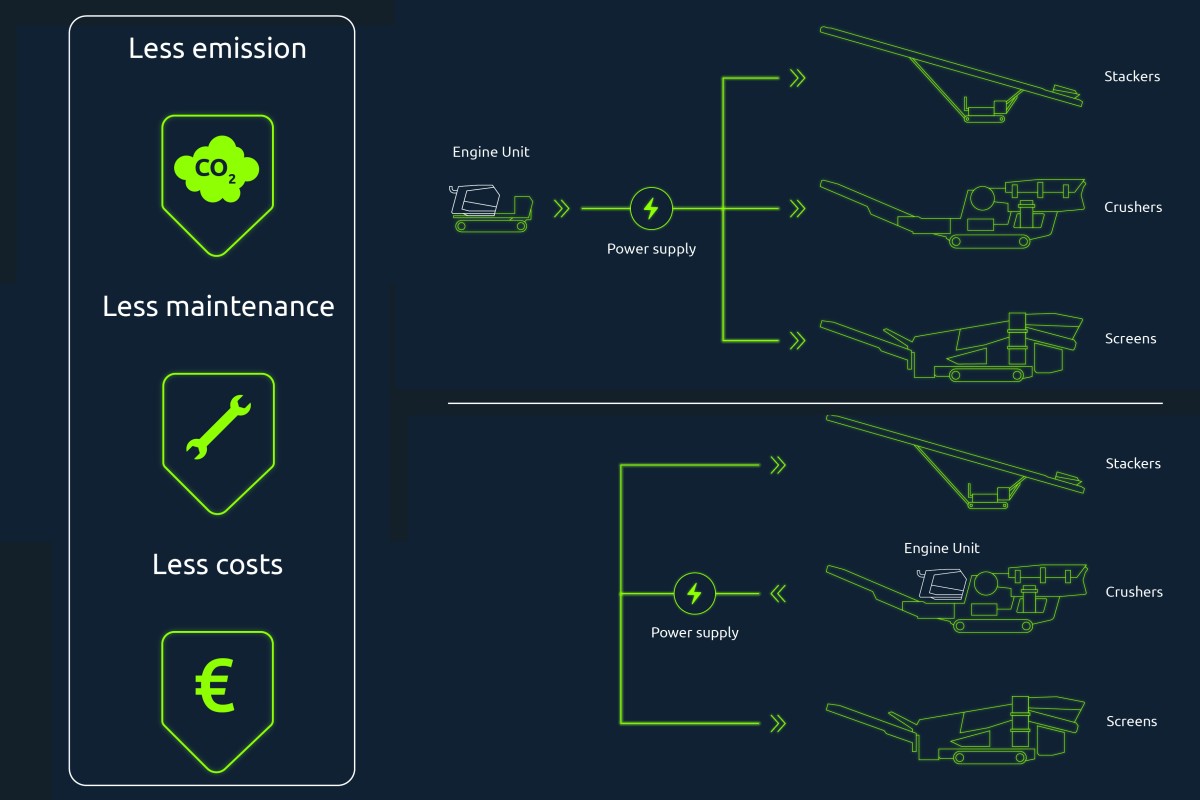

Keestrack, a major manufacturer in mining, recycling and construction equipment is known for using the best economic drive systems to power their equipment. They started with load sensing hydraulics in 1999 which reduced the fuel costs with 30%. Keestrack started using electric drives in 2012 and introduced the e-drive; electric plug-in with on-board diesel/gen-set in case there is no electric plug-in resource available. Keestrack will keep on searching for the best performance at the lowest costs and with the smallest ecological footprint. Nowadays Keestrack introduced the ZERO-drive machines, without any combustion engines on- board. Only electric motors drive the mobile crushing and screening equipment. At this point electric drive systems are the greenest and most effective options on the market, as they are more efficient than conventional hydraulic systems, however Keestrack will keep on searching for even better solutions to drive their equipment.

In Keestrack vision the same efforts and technology can be applied to the agricultural sector that is, and will always be, the protagonist of this revolution. In agriculture using sustainable energy will create a perfect circle. Producing food and preserving the environment by reducing the carbon footprint on the entire supply chain. This goal is even more challenging in specialized agriculture where high power is required and compact dimensions of the machinery are the main elements to deliver efficient solutions. It has been the goal for many years for Keestrack to enter this market and leverage the Keestrack know-how and background. Nowadays the time is ripe to present a brand new 100% battery driven narrow tractor, developed together with technological partner Rigitrac, a Swiss agricultural machinery manufacturer, who has been studying the electrical application to agricultural machinery for more than 11 years.

Rigitrac Traktorenbau AG, is a traditional family business based on extraordinary innovative strength of father Sepp sustained by his wife Marlis and their four daughters who manage with joy and conviction the main company functions. A constantly growing company counting on extremely competent and motivated employees.

Since 2003 Rigitrac has been building in Switzerland, in various model variants, which have already received various awards thanks to their entrepreneurial innovative strength. These tractors impress with their manoeuvrability and high stability on slopes and are built to be very gentle on the soil.

With the new, purely electric Rigitrac SKE 40 project, the company's spirit of invention and ingenuity has now reached another peak. The vehicle passed the extensive tests with impressive performance and is scheduled to go into series production next year. The mission profile is a versatile tractor ideal for road and lawn care in both summer and winter. Interested buyers are likely to be municipalities, green care professionals and sustainable agriculture farms. The Rigitrac SKE 40 Electric project combines the latest technology, low noise emissions, low operating costs, low maintenance requirements, environmental friendliness, resource conservation and a long service life. This makes it an environmentally friendly alternative to conventional vehicles.

The tractor will be produced in Italy at the Goldoni Keestrack factory, which is part of the Keestrack group since March 2021 after the acquisition of Goldoni. Keestrack found in Goldoni a perfect fit. A historical Italian manufacturer specialized in narrow agricultural machinery to lead a sustainable agricultural market.

Goldoni Keestrack is a renowned Italian manufacturer specialized in agricultural machinery production since 1926. It is a benchmark in compact and narrow agricultural machinery industry. From motorcultivator to specialized 4WD and Equal Wheels tractors dedicated to orchards and vineyards. The Goldoni range is developed to help agricultural operators manage the entire agronomic cycle more effectively and sustainable.

Ultime notizie di OnSite News

Components

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

Lifting

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

Earthmoving Machinery

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

Lifting

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

Services

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

Lifting

08/04/2024

First Sinoboom AB10J boom lifts for Australia

The first of Sinoboom's AB10J articulating boom lifts to arr...

Altri International

International

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

International

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

International

24/04/2024

New Palfinger's TEC Heavy-Duty Cranes Set Standards in Power & Precision

The new Palfinger PK 1350 TEC and PK 1650 TEC heavy-duty cra...

International

24/04/2024

SSAB and Manitou Group agree on fossil-free steel

Manitou Group announces the signature of a letter of intent...

International

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

International

23/04/2024

JCB expands Hydradig line-up with Plus and Pro models

JCB is meeting the needs of customers across every industry...