Home \ International \ New features of CAT 745 truck

New features of CAT 745 truck

15/03/2017

Pubblicato da Redazione

Offering a 45.2-ton (41-tonne) rated payload capacity, the new Cat 745 articulated truck features a world-class cab design, completely re-engineered from the inside-out using global operator feedback

Offering a 45.2-ton (41-tonne) rated payload capacity, the new Cat 745 articulated truck features a world-class cab design, completely re-engineered from the inside-out using global operator feedback to advance comfort and ease of operation. The new external “spinal” ROPS structure boasts bonded rear quarter glass that eliminates the structural pillar to give the operator a dramatic improvement in visibility from the cab. Upon cab entry, the new “wake up” feature initiates machine displays as soon as the door is opened, while the lighter/stronger cab door offers shut assist for improved sealing against dust infiltration. The quieter cab design lowers inside sound levels by 5 dB at the operator’s ear.

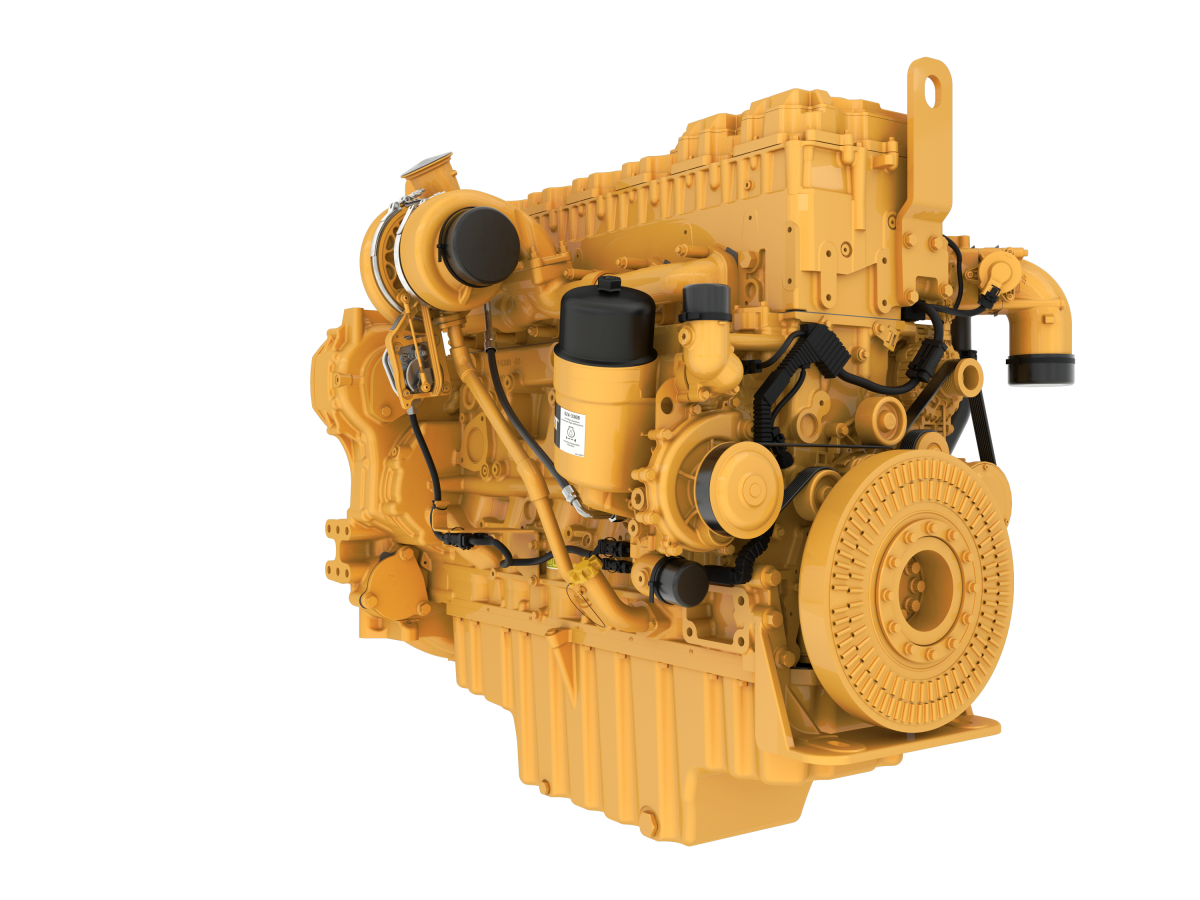

The new Cat 745 articulated truck incorporates all the field-proven features and performance of the C Series that deliver fast cycle times, high productivity and unmatched fuel efficiency for its class. Its powertrain is driven by the Cat C18 ACERT engine, rated at 504 net HP (375 kW), which meets U.S. EPA Tier 4 Final/EU Stage IV emissions standards. A new economy mode feature results in an average of 5 percent fuel consumption improvement in applications where a truck is not required to operate at full productivity.

Cat’s CX38B High Density Power Shift transmission enhances the new truck’s overall performance and productivity, while permanent six-wheel drive enables the truck to navigate even the most challenging terrain. Automatic retarding control manages machine retarding through a combination of engine, brake, gear selection and service brake application without operator intervention. Hill assist facilitates efficient stopping and starting on grades, while the Waiting Brake system, quickly engaged by a push-button on the control lever, temporarily applies the service brake during pauses in the work cycle.

In direct response to customer feedback, the lower portion of the front fenders is now made of a durable and flexible rubber sheet material. This change will help decrease maintenance and repair costs on sites where mud packing around the fenders could damage the lower section. Cat Connect Payload technology for the new 745 truck allows customers to optimize operations and improve overall jobsite efficiency. The available Cat Production Measurement system gives operators the ability to measure and deliver accurate payload with the confidence to boost productivity, lower costs and reduce the risk of overload damage.

Ultime notizie di Caterpillar - CGT

Earthmoving Machinery

18/01/2024

Caterpillar Signs Strategic Agreement with CRH

Caterpillar Signs Strategic Agreement with CRH for Electric...

Earthmoving Machinery

06/12/2023

Caterpillar to Amplify Electrification and Energy Solutions at CES 2024

This year’s display focuses on Caterpillar’s electric machin...

Components

27/11/2023

Caterpillar to Develop Hydrogen-Hybrid Power Solution for Off-Highway Vehicles

Starting in early 2024, the advanced hydrogen-hybrid project...

Earthmoving Machinery

10/11/2023

Freeport-McMoRan uses Cat MineStar to convert fleet

Caterpillar and Freeport-McMoRan (FCX) announce that the two...

Earthmoving Machinery

13/10/2023

Caterpillar celebrates production of the 50,000th Cat Wheel Excavator

Caterpillar announces production of its 50,000th wheel excav...

Earthmoving Machinery

17/07/2023

The new Cat 995 Wheel Loader features increased productivity

New Cat 995 Wheel Loader offers more payload and performance...

Altri International

International

20/05/2024

Correct Maskin AS as new Jekko’s official dealer in Norway

ekko announced the addition of Correct Maskin AS to its sale...

International

20/05/2024

Kleeman presentes the MOBISCREEN MSS 502(i) EVO

The new scalping screen MOBISCREEN MSS 502(i) EVO from Kleem...

International

17/05/2024

Volvo CE has taken a 22% ownership stake in VizaLogix

Volvo CE has taken a 22% ownership stake in VizaLogix, a US-...

International

17/05/2024

Manitowoc donates crane simulator to IUOE’s training center in Texas

• Manitowoc has provided cranes and technical support to eve...

International

16/05/2024

Boulard TP banks on Liebherr Crawler Dozers

Once again, this year France was home to the biggest motorcy...

International

16/05/2024

Sinoboom marks South American milestone with opening of Brazil subsidiary

Over 100 Brazilian rental company customers attended the con...