Home \ International \ Rototilt investing SEK 35 million in state-of-the-art expansion

Rototilt investing SEK 35 million in state-of-the-art expansion

29/01/2024

Pubblicato da Redazione

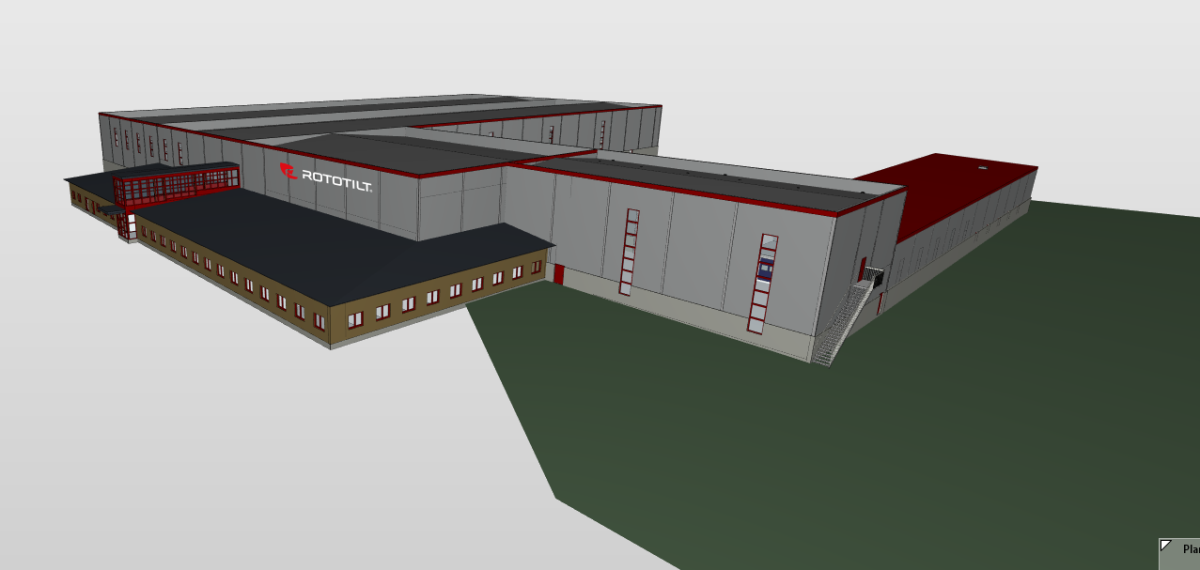

Rototilt, which develops and manufactures tiltrotators for the global market, is investing heavily in the future by expanding its factory in Vindeln, Sweden.

Rototilt, which develops and manufactures tiltrotators for the global market, is investing heavily in the future by expanding its factory in Vindeln, Sweden.

The extensive investment includes the development of a state-of-the-art robotic welding facility at a cost of approximately SEK 35 million.

“Even though the economic situation is challenging right now, we believe in continued growth and require greater flexibility and capacity in order to meet our customers’ high demands. This investment is strengthening our position, enabling us to deliver with speed and precision, which is crucial in our market segment,” says Anders Jonsson, CEO.

A new robotic welding system is currently being introduced, linking up handling robots and welding robots. The investment is generating customer value by providing opportunities for improved delivery times and quality. The construction project, which was launched in October 2023, includes an expansion of the factory totalling 1080 m2, spread over two floors. The new welding section will be ready for final inspection in May 2024.

“The global situation is placing new demands on us, and we are dealing with this at the same time as attempting to develop our business. We are now creating the conditions to improve our delivery precision, which is something we are constantly focusing on, since we know how important it is for our customers,” says Anders.

Rototilt’s production facility is powered by fossil-free energy, and the extended factory is being built with an advanced energy recovery system. The heat from the welding process is recovered via the ventilation system, thereby reducing both energy consumption and the climate footprint. The factory’s primary heating source is district heating, which is produced from local biofuel.

“The new welding facility will contribute to a lower proportion of goods transport. All the elements that are contributing are important, and we are constantly thinking about how we can reduce our climate footprint,” says Ida Skaring, Sustainability Strategist at Rototilt.

During the autumn, Rototilt has also invested in one of Sweden’s largest private charging parks, with 178 vehicle spaces outside the factory in Vindeln. All the parking spaces are equipped with sockets for engine heaters as well as electric car charging.

“We are proud to be creating a greener workplace and to be supporting the ongoing transition to sustainable travel. Half of our employees commute from other municipalities, and this development is making it easier for anyone who drives an electric car to get to the workplace. It will hopefully also encourage more people to switch to an electric car. Our aim is not only to offer innovative products, but also a production facility that is in line with the highest sustainability standards,” says Anders.

Ultime notizie di OnSite News

Components

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...

Components

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

Lifting

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

Earthmoving Machinery

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

Lifting

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

Services

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

Altri International

International

03/05/2024

JCB: New factory-fitted machine control solutions launched

JCB and Leica Geosystems, part of Hexagon, today announced t...

International

30/04/2024

JCB's new generation backhoes bring greater levels of versatility

JCB unveils a number of key improvements to its backhoe load...

International

29/04/2024

Wirtgen's global market launch: Rock Crusher WRC 240(i)

Rock Crusher WRC 240(i) is the new Wirtgen's specialist for...

International

29/04/2024

JCB updates X Series excavators with the launch of JCB UX

JCB has updated the interior of the X Series excavator opera...

International

26/04/2024

Digitalisation and sustainability at the Wirtgen Group's "Technology Days"

Digitalisation and sustainability were the focal points of t...

International

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...