Home \ International \ Simex: a key innovator at Intermat 2018

Simex: a key innovator at Intermat 2018

11/05/2018

Pubblicato da Redazione Redazione

At Intermat Simex showed out new products, demonstrating once again the company’s ability to provide solid solutions to the needs of users around the world.

At Intermat 2018 Simex showed out new products, demonstrating once again the company’s ability to provide solid solutions to the needs of users around the world.

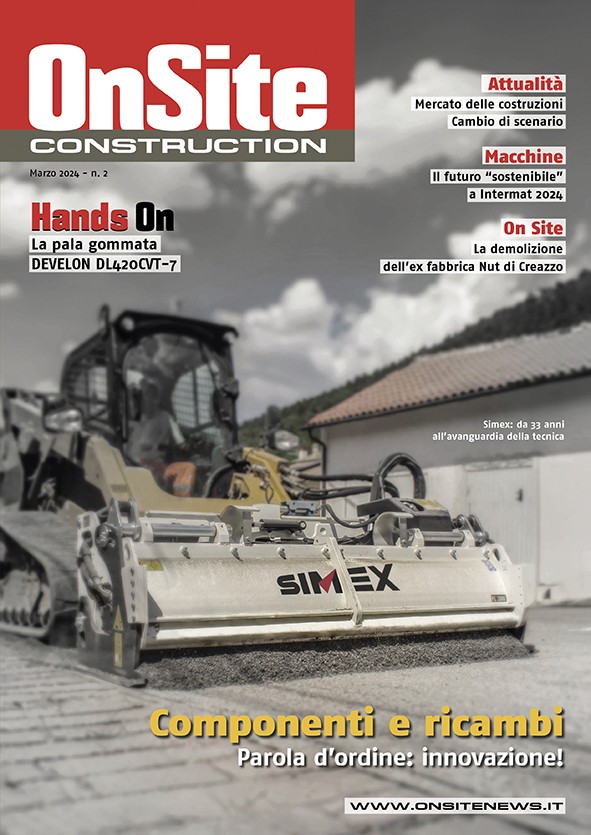

With a turnover on the increase (+17%) compared to 2017 Simex, active since 1991, is one of today’s most important producers of attachments for machines used in road maintenance, trenching for utilities installation, cabling and recycling. Simex offers a wide range of solutions covering a broad spectrum of applications thanks to 19 product lines for a total of 74 models.

Relying on an organization of over 100 employees, many of them specialized, Simex exports to over 80 countries and is a holder of several patents, the result of constant efforts to innovate, a mark of the company since its founding. The ability to pinpoint solutions designed to solve the widest range of problems is a key strength of the company, which consistently produces attachments that guarantee productivity and profitability.

The strength of research and development

The global success of Simex attachments is also attributable to an R&D department staffed with professionals holding valuable experience. They combine the rigorous process of testing and experimentation of the new products with remarkable flexibility in their search for cutting-edge solutions that effectively respond to the requirements of many different markets.

It is the company’s great capacity for listening to customers to make this possible, in addition to a production process prioritizing quality above all.

Innovative and efficient attachments

Simex got its start by producing road planers designed to be coupled to compact machines and some types of machines fitted with booms (with a range of 12 models, Simex is currently the first producer in the world for this specific type of attachment). The company later developed wheel saws and chain excavators, then proceeded to produce cutter heads (the first in the world to be fitted with a coaxial hydraulic motor). The range was then added with vibrating wheel compactors and pavers, completing the line of attachments for road applications. Succeeding these models came the crusher buckets and screening buckets, both featuring a new concept that enabled higher productivity, also in conditions defined as “difficult” by other producers.

Similarly, the launch of the line of Simex VSE screening buckets (presently including four models) created a new standard for this type of equipment: the VSE screens different types of materials and allows the output size to be varied without performing complicated or time-consuming mechanical procedures.

Thanks to a patented mechanism, the Simex VSE screening buckets perform hydraulic adjustment of drum distance to allow a variation in output size of the material in seconds. The patented system of the Simex screening bucket also enables easy replacement of screening elements, making the attachment adaptable to different types of applications.

With over 50000 attachments produced that operate across every continent and in the toughest, most extreme working conditions, Simex has built a solid reputation as a dependable producer that allows users to obtain levels of productivity and profitability otherwise unattainable.

First also for fiber optics

Mini-trenching has been unanimously elected the best solution for installing fiber optic networks, a fast developing sector these days, especially in Europe. This type of trenching guarantees reduced operating costs and times with respect to traditional trenching, and above all a lower environmental impact, especially in urban settings.

With the wheel saws of the RW line, Simex offers the most efficient attachment available on the market today for mini-trenching. The RW wheel saws guarantee rapid job completion without producing large quantities of waste material. At the same, this attachment assures clean and precise trenches that require minimum maintenance, also of the wearing surface.

The Simex range includes wheel saws from both the RW and T lines that excavate mini-trenches having a width of 25-250 mm and depth of 200-800 mm. The company also produces wheel saws designed to respond to the specific requirements of different countries tasked with expanding their fiber optic networks.

Last October, in fact, Simex organized a workshop including field demonstrations for a group of important German companies operating in the sector of fiber optic networks. During the round table discussion participants exchanged views and opinions, emphasizing the demands and problems that must be confronted and solved in Germany. The workshop further validated the international success of the company’s solutions for the installation of fiber optic networks.

Intermat also served as an opportunity to introduce new models of wheel saws and other attachments that can be used in the excavation of mini-trenches.

Ultime notizie di Simex

Equipments

10/02/2023

Commercial breakthrough for Simex in the US

On the occasion of Conexpo-CON/AGG 2023 Simex will launch on...

Equipments

27/09/2022

Simex RWE 100 wheel saw for demolition in Lucerne

LötscherPlus has relied on the Simex RWE 100 wheel saw, the...

Equipments

28/07/2022

New Simex PL 2000 road cold planer

The new Simex PL 2000 road cold planer is destinated to asph...

Equipments

19/07/2022

Crushing of reinforced concrete directly on site with the Simex CBE 40 crusher bucket

Great productivity and reliability for the Simex CBE 40 faci...

Equipments

29/06/2022

Simex and the importance of asphalt milling recycling

An considerable step forward for companies in the sector of...

24/05/2021

Trenching for drainage pipes along Shanghai subway

Through its importer ATE, Shanghai Construction Group (SCG)...

Altri International

International

16/04/2024

Kleemann's SPECTIVE CONNECT: now new with Tool Management

The intuitive SPECTIVE operating concept makes a significant...

International

15/04/2024

Liebherr tower cranes renovate bridge in Spain

Two Liebherr 420 EC-H 16 Litronic cranes are secured to the...

International

15/04/2024

JCB completes ride-on tandem roller range with CT380/430

Global equipment manufacturer JCB has added the CT380-130 an...

International

12/04/2024

Manitowoc launches two new Potain luffing jib cranes

• Manitowoc is introducing two new luffing jib crane models,...

International

12/04/2024

CASE to show wheel loader and crawler excavator additions at Hillhead 2024

CASE to show wheel loader and crawler excavator additions at...

International

11/04/2024

Hitachi presents pioneering safety technology on Zaxis-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will exhib...