Home \ International \ Success for JLG at Apex

Success for JLG at Apex

10/05/2017

Pubblicato da Redazione Redazione

JLG Industries, Inc. showcased a range of forward-looking technologies and innovative equipment designed to increase productivity, lower total cost of ownership, and improve safety on the jobsite

JLG Industries, Inc. showcased a range of forward-looking technologies and innovative equipment designed to increase productivity, lower total cost of ownership, and improve safety on the jobsite during Apex 2017.

Developed to boost operator productivity, JLG featured a static demonstration of a JLG concept boom positioned on uneven terrain, which displays the machine’s self-leveling chassis automatically leveling itself in a longitudinal and/or horizontal direction, depending on the demands of the terrain. The self-leveling chassis reduces three-wheeling, allowing the machine to maintain traction on sloped or uneven ground. Machines equipped with a self-leveling chassis can traverse slopes up to 10 degrees with the boom elevated, which means greater uptime and less repositioning. This feature allows easier loading, unloading, and transport, as the chassis can be lowered to reduce the total height of the machine. A transparent organic light emitting diode (OLED) screen will show the self-leveling chassis working through several jobsite scenarios, including traversing uneven terrain, offloading from a flatbed truck, and working at height on uneven ground.

JLG also highlighted SkyGuard, its control panel protection system, at the booth. Earlier this year, JLG announced SkyGuard is standard equipment across the entire JLG portfolio of boom lifts. When activated, the revolutionary SkyGuard system stops all functions in use at the time, then temporarily reverses or undoes most functions that were in use when the system was activated. This reverse functionality is the first in the access industry. SkyGuard can be activated from a variety of angles and provides additional protection without impeding or reducing the work envelope of the boom lift. Nor does it increase the boom lift platform profile or limit the use of the platform. The system resets with a cycling foot switch or e-stop, and with no moveable parts, it eliminates the need for scheduled or additional maintenance. SkyGuard kits are available to customers for specific models of boom lifts ordered prior to 2017.

Additionally, JLG showcased a second safety-focused technology – the No Touch Enhanced Detection System (EDS) for scissor lifts, which is an advancement of the company’s existing Soft Touch System. Soft Touch uses whisker proximity switches to stop a machine when it makes contact with an object or structure. No Touch EDS uses advanced infrared technology to sense an object or structure nearby – first slowing, then stopping the machine before it makes contact. A visual and auditory warning alerts the operator when a boom or scissor approaches a structure. No Touch EDS then stops the machine, limiting its operation to reverse mode, unless the operator overrides the system to inch closer to complete the work at hand. If the operator doesn’t override the system, the machine remains in reverse mode until it is safely clear of the obstruction, when it will return to normal operation. No Touch EDS is ideal for aviation, aerospace, and other industries where operation near costly structures requires extra care.

To help equipment owners lower total cost of ownership, JLG demonstrated its telematics technology and the future of training with its lift and access equipment simulator.

Ultime notizie di JLG Industries Italia

Altri International

International

19/04/2024

Hitachi presents specially adapted ZX390TC-7 excavator at Intermat

Hitachi Construction Machinery (Europe) NV (HCME) will displ...

International

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

International

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

International

18/04/2024

JCB: Stage V Powertrain for large platform Skid Steer Loaders

JCB has launched EU Stage V compliant versions of its large...

International

17/04/2024

Color change signals bold new era at Yanmar CE

Yanmar Compact Equipment is undergoing a shift in its approa...

International

17/04/2024

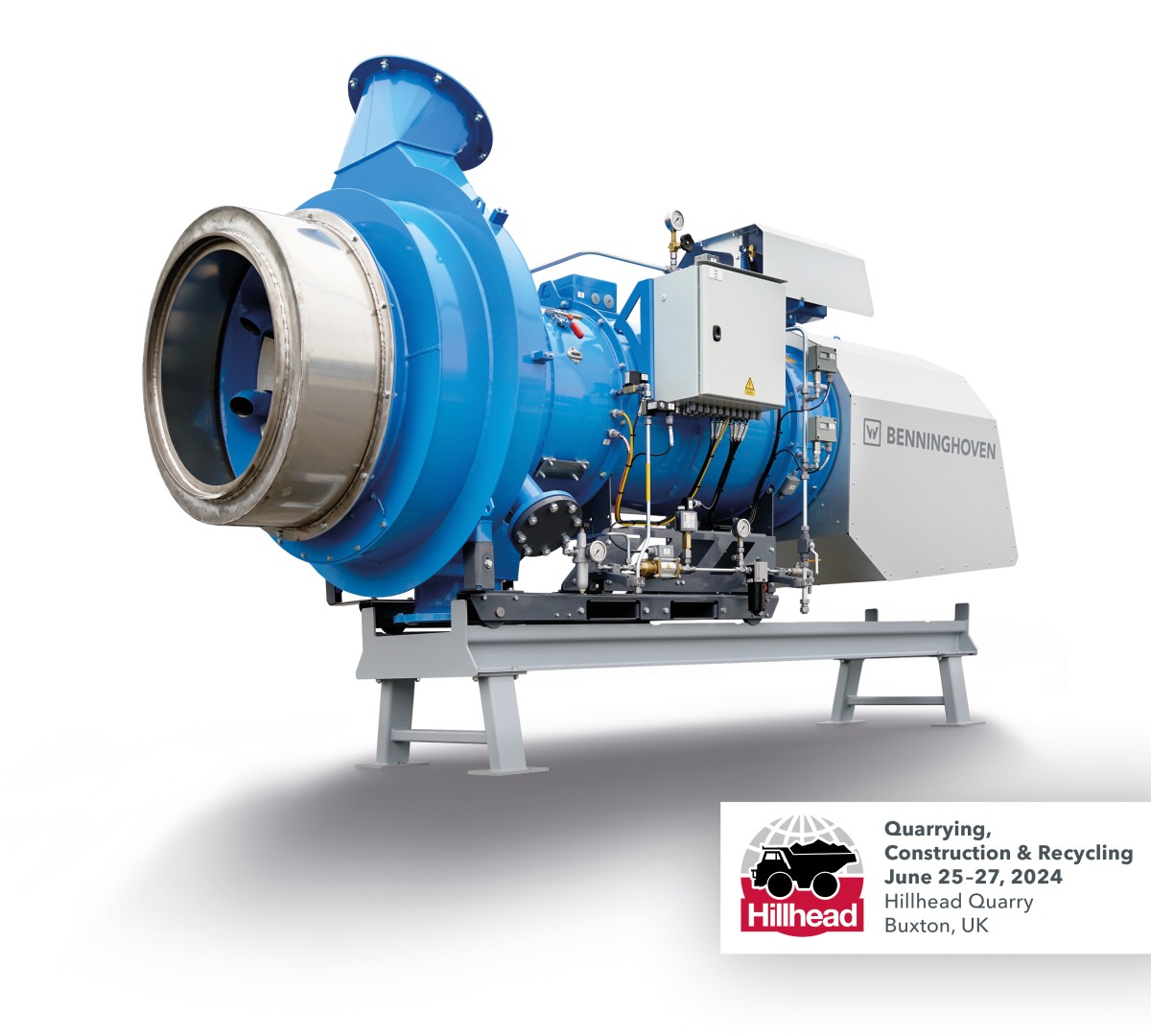

Wirtgen Group presents numerous premières for the British market

Smarter. Safer. More Sustainable. This is the theme of the W...