Home \ International \ Summit Constructors builds with Trimble 3D Machine Control

Summit Constructors builds with Trimble 3D Machine Control

06/08/2018

Pubblicato da Redazione

Nashville-based contractor SUMMIT Constructors improves grading accuracy, speed and excavation with help from Trimble machine control and Business Center-HCE

Customer Profile: Summit Constructors is a leading grading contractor in Nashville, Tennessee. The company specializes in grading for residential, commercial and industrial applications, underground utility construction, road construction and municipal buildings. The company has over 200 employees and more than 200 pieces of earthmoving equipment.

Business Challenge: Summit Constructors was hired as a subcontractor to build a one million square foot pad for a major sports apparel and equipment company headquartered in Tennessee. Phase one of the almost $9 million contract had an extremely tight four-month deadline for grading. Looking for help, the company turned to Sitech and Trimble.

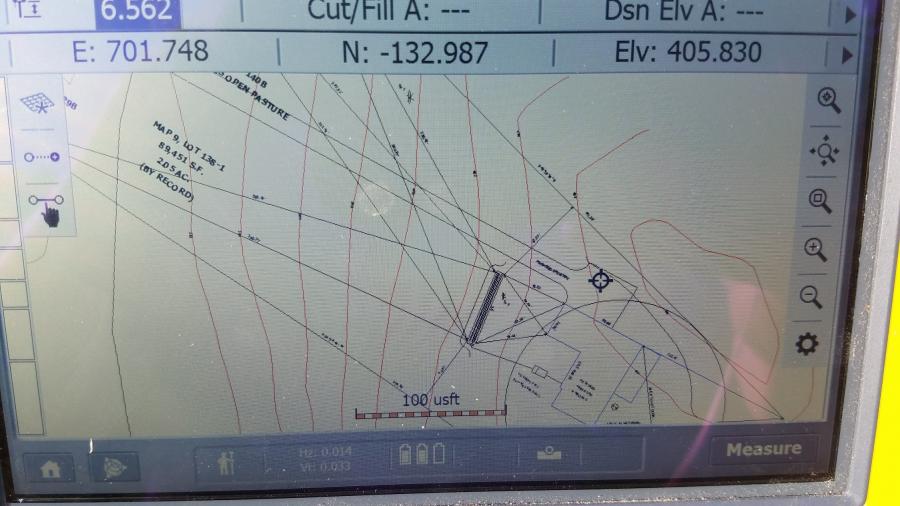

Solution: Trimble SPS855 GNSS Modular Receivers, Trimble GSC900 Grade Control Systems, Trimble SCS900 Site Controller Software, Trimble SPS985L GNSS Smart Antennas, Trimble SPS930 Robotic Total Station, Trimble Site Mobile Software, Trimble data collectors and Trimble Business Center- Heavy Civil Construction Edition (HCE).

Benefits: cut field staking by 50%, including zero blue topping for one million square foot building pad; 30% times savings with minimized finish grading needed; used dozer to put down shot rock to within one-tenth of an inch; reduced field calculations by 75%; one model including curb and gutter layout shared with subcontractors added quality and reduced time required for overall build; excavated shot rock for 67-acre site to hit 38-foot fill; zero rock had to be brought into the site. Not having to import this material resulted in a $130,000 savings.

Summit Constructors has built its business steadily over the past 20-plus years by providing excellent service and results. The grading and utility contractor is also well known for its experience in blasting rock and working through the tough limestone bedrock that surrounds the Nashville area and Central Basin.

The company was hired by Alston Construction as a subcontractor for the construction of a new one million square foot distribution facility for a major sports equipment and apparel company just west of Nashville. Phase one of the project involved moving 700,000 cubic yards of total material and clearing the 67-acre site for the building pad. The company was given a tight four-month deadline for this work, with liquidated damages of approximately $13,000 a day for missing the timeline.

Because of a lackluster experience with another machine control product, the company’s managers determined they needed to explore other options. After attending Trimble’s semi-annual user conference, Trimble Dimensions, Summit Constructors project manager and estimator J.D. Edwards and his colleague David Haggard, survey manager, decided to give some of the equipment they saw at the show a try. They worked with their local Trimble dealer, Sitech Tri-Rivers, to get up and running on Trimble equipment. Over the span of two years, the team equipped 10 dozers with machine control, and purchased six base stations and four Trimble SPS985L GNSS Smart Antennas for field rovers with Trimble SCS 900 software. They also purchased two sets of Trimble SPS855 GNSS Modular Receivers and Trimble Business Center-HCE.

Brandon Bates, technology support specialist at Sitech Tri-Rivers, worked with Summit Constructors to set up four Trimble GNSS base stations, the machine control systems and Trimble’s SCS900 Site Controller Software and data collectors. The data collectors would be used for grade checking, staking and measuring as-builts.

Two months into the project, they added another larger dozer and one finishing dozer for fine grading and completing smaller areas with final touches. At any given time during the project, Summit Constructors had 30 pieces of heavy equipment working on the site, including 14 off-road, haul trucks for moving rock.

Within days of selecting the Trimble technology solutions, Bates was out on the jobsite setting up the equipment and getting the operators familiar with the technology. Bates spent about one day with each operator and surveyor on training. “We had tried another manufacturer’s technology in the past, but with that vendor we had to wait several days when we had a problem and we just had to stop working,” said Haggard. “That wasn’t an option on this project. We were blown away by the fact that Brandon from Sitech was so responsive – he was there within an hour if we needed him. But the stability of Trimble systems is the big thing. Our operators are now fighting over the Trimble equipment; every time they turn the key, everything is working and they’re ready to roll”.

Edwards explains that before using Trimble technology, site positioning tasks were much more time consuming. Survey crews had to calculate storm and sewer locations manually. Now they’re using Business Center - HCE and data collectors to intersect and pinpoint locations and trim, and extend and offset lines directly in the field. “Our survey crew used Trimble’s SCS900 Site Controller Software and data collectors to calculate volumes and do topo work much more efficiently than traditional methods,” said Edwards. “This was important because we were able to make sure our quantities were absolutely correct. With that accuracy, we had a balanced site, meaning we hit a 38-foot fill on one end of the pad and we didn’t have to bring in any rock. This allowed us to hit our milestone dates and we saved about $130,000 by not bringing in fill material.”

3D machine control on dozers lets Summit Constructors put down shot rock to within one-tenth of an inch for the building pad. Running off Haggard’s model, the team set very few stakes on the project. Edwards believes accurate grading with the dozers saved about 30% in time savings because there was minimal clean up and fine grading needed.

Haggard explains that during the project, he began to experiment with Business Center - HCE in combination with other conventional modeling software. Haggard plans to continue learning Business Center - HCE’s data preparation, image manager and surface tools modules. “The main contractor on the project had to get used to not seeing many stakes in the field because in the past they were everywhere,” said Edwards. “Our foreman would take the rover out there and show him where the corner of his building was and where we were hitting grade. After a while he was just really impressed at our operation; it showed that we were investing in this high-tech equipment and it was helping us work faster and more accurately − which is a big deal for winning more work.”

With Business Center - HCE, Haggard explains that he can build constructible models in hours instead of days compared to other software, and then share those models with other subcontractors, like the curb and gutter workers on site. “There used to be a constant battle out there about which model to use; luckily we all tried to work together, but it was a challenge when, for example, pavers would overrun the aggregate and blame us because it’s our subgrade,” said Haggard. “On this project, the pavers came out and used my model to do all the paving and all the curb layout. Using Trimble systems and our models, you can get everybody on the same page on the front-end, and that reflects very positively on us.”

After meeting the four-month phase one deadline, Summit Constructors was also hired to build a second, 1.5 million square foot pad for a large vehicle manufacturer in Smyrna, Tennessee. For this project, the team utilized a Trimble Universal Total Station for the first time. The Summit team used the robotic total station control grading operations due to limited GPS reception around standing walls. To complete the building pad, Summit used Trimble GSC900 machine control on three dozers. These six-way blades were used for dozing and scraper work, plus finish grading. Edwards explains that operators were impressed that they could hit grade − plus or minus one-tenth of an inch − without bringing in a motor grader for finish grade work. The pad was completed accurately and on time.

Since that project, Summit has added an additional dozer equipped with Trimble grade control, as well as two additional base stations and two SPS985L field rovers. Edwards explains that site positioning equipment and machine control from Trimble along with support from Sitech have helped Summit increase competitiveness and deliver high-quality results for customers. Today, the team can finish complex jobs more quickly, which saves money and frees up motor graders and other equipment for other proj

Ultime notizie di Trimble

28/02/2019

Trimble to showcase connected construction at Bauma 2019

Trimble to Showcase Connected Construction at bauma 2019

02/08/2018

German contractor completes complex landscape design with Trimble technology

Franz Darger Garten- und Landschaftsbau completes a Libeskin...

23/07/2018

Faster and more accurate excavation with Trimble in Ohio

Leading earthworks contractor tests Trimble’s new mach...

17/07/2018

"Dirt Ninja" small contractor finds big dividends with machine control

Small site contractor uses Trimble Site Positioning Systems...

Altri International

International

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

International

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

International

24/04/2024

New Palfinger's TEC Heavy-Duty Cranes Set Standards in Power & Precision

The new Palfinger PK 1350 TEC and PK 1650 TEC heavy-duty cra...

International

24/04/2024

SSAB and Manitou Group agree on fossil-free steel

Manitou Group announces the signature of a letter of intent...

International

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

International

23/04/2024

JCB expands Hydradig line-up with Plus and Pro models

JCB is meeting the needs of customers across every industry...