Home \ International \ Three Liebherr tower cranes in action in Hamburg's HafenCity area

Three Liebherr tower cranes in action in Hamburg's HafenCity area

15/12/2023

Pubblicato da Ettore Zanatta

Construction of Germany's tallest timber high-rise underway with the help of Liebherr fibre rope cranes.

19 storeys, a building height of 65 metres, and three Liebherr tower cranes: a unique building is currently under construction in Hamburg's HafenCity area. An interplay of reinforced concrete and timber frame structures, fibre cranes, and a location on the banks of the Elbe River make this project something special. “The deciding factor for using two cranes with fibre rope was the high hook height involved – the 370 EC-B Fibre has the fastest lifting speeds compared to its competitors," says Christopher Bäcker, Field Sales Manager at Friedrich Niemann GmbH & Co. KG, outlining what was needed to keep the site running in 2-shift operation.

The construction machinery dealer, based in Kronshagen near Kiel, delivered two 370 EC-B 12 Fibres with hook heights of 87.7 and 77.4 metres to Hamburg. Their radius measured in at 60 and 47.7 metres respectively. The third crane involved was a 250 EC-B 12 with a hook height of 35 metres and a radius of 44.15 metres. All three machines were new cranes from Niemann’s rental fleet.

Opting for fibre rope saves a substantial amount of weight for Friedrich Niemann GmbH & Co. KG. Steel ropes would weigh a great deal more due to the high hook height of both 370 EC-B cranes. Christopher Bäcker is impressed by the fibre rope, “Using fibre rope makes perfect sense for us given this hook height, as otherwise we would be hauling several 100 kilograms of steel rope with us and lose a whole lot of lifting capacity.” The high-tensile fibre rope enables up to 20 percent higher jib head load capacity compared to its steel rope counterpart. Service life is four times longer than that of a steel rope with the same amount of use. The 370 EC-B Fibre has a maximum hook height of 91.7 metres, a 12-tonne maximum lifting capacity, and a maximum radius of 78 metres. 2.8 tonnes can still be moved at its jib head at full radius.

One of Europe's largest inner-city urban development projects, Hamburg's HafenCity area, is being built where docks and old warehouses once stood. The timber high-rise “Roots” is under construction in the Elbbrücken district, and will feature 181 apartments with views of Hamburg, the harbour, and Elbe waterways. The “Roots” consists of a 19-storey high-rise tower and an adjacent building with seven floors. Around 5,500 cubic metres of construction timber are being used for the building, a world record. This total doesn't include the material used for façades, windows, and cladding. Many components have been delivered to site prefabricated.

Its waterfront location requires a special flood protection concept: a basement level inspired by the traditional North Sea “warft” model, with a height of eight to nine metres above sea level, serves as protection against flooding in Hamburg's HafenCity; this doubles up as an underground car park. Two storm surges have already occurred during construction, making the project challenging for everyone involved. Flood protection is also evident in the materials used: the “warft” basement and lower levels have a reinforced concrete structure, while ceilings and walls are made entirely from timber from the third storey upwards. The cranes were used for lifting both concrete and timber parts, which required close consultation between the companies involved and solid coordination in terms of day-to-day work on site.

The PEFC-certified timber from sustainable forestry has been largely sourced from Styria in Austria, one of the most densely forested regions in Europe. Load-bearing walls are primarily made from spruce wood, but smaller quantities of pine, fir, and beech wood have also been incorporated. Construction on the “Roots” officially began on 27 November 2020 and the foundation stone was laid on 13 September 2021. Timber components, finished with millimetre precision, started arriving on site in May 2022. The first lift for the "Roots" involved a façade element weighing 2.6 tonnes and measuring 10.3 metres by 2.6 metres. An easy job for the 370 EC-B 12 Fibre with a radius of 60 metres. Most of the subsequent façade elements arrived on site with windows and balconies already installed. The wall panels were frequently complex in shape as a result of this extensive prefabrication and had to be attached to the crane hook using a lifting beam. This meant determining the exact attachment points on the beam in advance to ensure that the load was balanced during lifting and not pulled upwards at an angle. Around 1,200 prefabricated timber components of varying sizes and weight have been used for the timber tower. The heaviest component weighed around eight tonnes and measured just under 14 metres in length. A total of 400 timber components make up the adjacent building. Modular construction with a high degree of prefabrication saved both time and money on site. The resulting reduction in noise pollution was an additional advantage.

The three Liebherr flat-top cranes were erected free-standing and mounted on foundation anchors on the Hamburg site back in June 2021. Both 370 EC-B Fibre cranes were assembled with the help of a Liebherr LTM 1450-8.1 mobile crane, with one of the two fibre cranes then being used for the 250 EC‑B 12. The 250 EC-B was dismantled in the same way as it was assembled, again through one of the two 370 EC-Bs. One 370 EC-B was then dismantled by its brother. The remaining 370 EC-B was dismantled in October 2023, again by means of a Liebherr LTM 1450-8.1 mobile crane. This wasn't the first job for Liebherr tower cranes in Hamburg's harbour area: 25 tower cranes worked simultaneously in the Überseequartier district in 2021.

Three Hamburg-based companies are behind the design and development of the high-rise building: architectural firm Störmer Murphy and Partners, Garbe Immobilien-Projekte, and the German Wildlife Foundation. On its completion, planned for the first quarter of 2024, the building will offer 15,000 m² of living space and 430 m² of hospitality space for approx. 200 people. The German Wildlife Foundation will move in on the ground floor and use parts of the "warft” basement; its offices will be located on the first floor.

Ultime notizie di Liebherr Italia

Lifting

22/04/2024

Liebherr is part of the largest construction project in Greenland's history

Around 250 kilometres north of the Arctic Circle, Liebherr i...

Lifting

15/04/2024

Liebherr tower cranes renovate bridge in Spain

Two Liebherr 420 EC-H 16 Litronic cranes are secured to the...

Lifting

08/04/2024

150-tonne lifting capacity: Liebherr expands its telescopic crawler crane line-up with the LTR 1150

Liebherr has expanded its range of telescopic crawler cranes...

Lifting

11/03/2024

Expertise and Liebherr power in a two-pack

Liebherr LTM 1650-8.1 and LTM 1450-8.1 from MSG Krandienst a...

Lifting

12/01/2024

Liebherr L1 fast-erecting crane at work inside Passau Cathedral

Liebherr L1 fast-erecting crane at work inside Passau Cathed...

Lifting

09/01/2024

Riga Mainz replaces old railway bridge with Liebherr crawler crane LR 1750/2

Riga Mainz utilized a Liebherr LR 1750/2 crawler crane to re...

Altri International

International

26/04/2024

Digitalisation and sustainability at the Wirtgen Group's "Technology Days"

Digitalisation and sustainability were the focal points of t...

International

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...

International

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

International

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

International

24/04/2024

New Palfinger's TEC Heavy-Duty Cranes Set Standards in Power & Precision

The new Palfinger PK 1350 TEC and PK 1650 TEC heavy-duty cra...

International

24/04/2024

SSAB and Manitou Group agree on fossil-free steel

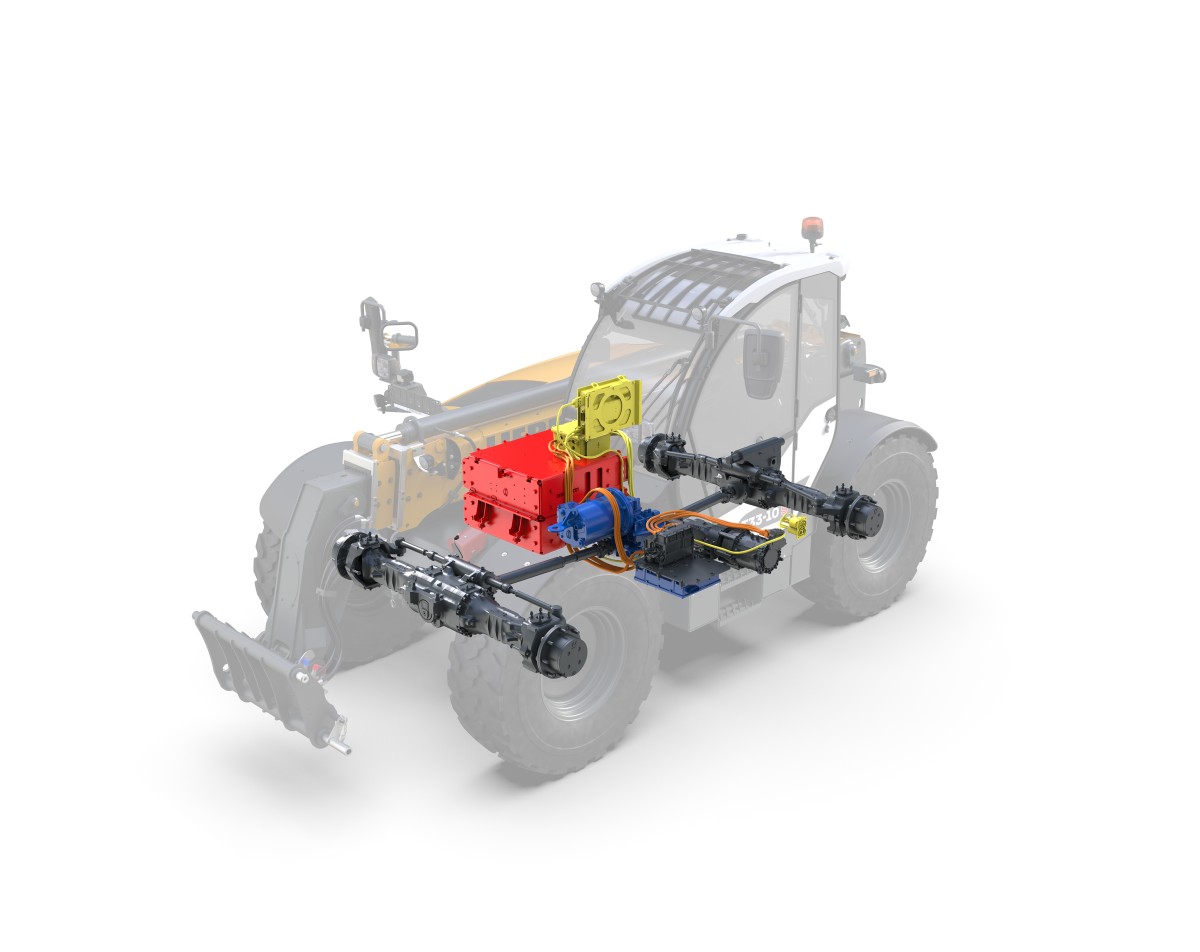

Manitou Group announces the signature of a letter of intent...