Home \ International \ AMCS technologies reveals its telematics: the IoT Lifting

AMCS technologies reveals its telematics: the IoT Lifting

05/03/2019

Pubblicato da Redazione

The company specialized in anti-collision safety systems and zoning for lifting machines has developed its own telematics called IoT Lifting.

The company specialized in anti-collision safety systems and zoning for lifting machines has developed its own telematics called IoT Lifting.

A tool to access concrete and real-time technical data about the anti-collision systems and the use of the crane has been developed to meet a real need of its customers. It centralizes all the information transmitted by the DCS 61-S anti-collision systems for each crane to a web portal and generates customized statistics for each job site and company.

"All our customers, if they wish, will have a daily feedback on the productivity of their construction sites and cranes equipped with our anti-collision DCS 61-S systems," says Mr. Chettibi, president of AMCS technologies.

How does the IoT Lifting of AMCS technologies work?

Step 1: Information is continuously collected by the DCS 61-S system thanks to the various sensors placed on the crane. Thanks to the 3G / 4G network of the SIM card placed in the modem of the system, it is thus possible to store, send and receive information on a web portal: the IoT Lifting.

Step 2: Each customer can connect to this secure telematics thanks to personal identifiers and password. The user will have access to the cartography of all the job sites of his company equipped with DCS 61-S.

Step 3: All the data relating to each crane and construction site are generated (hours at which the crane is under tension, in motion, in weathervane ...).

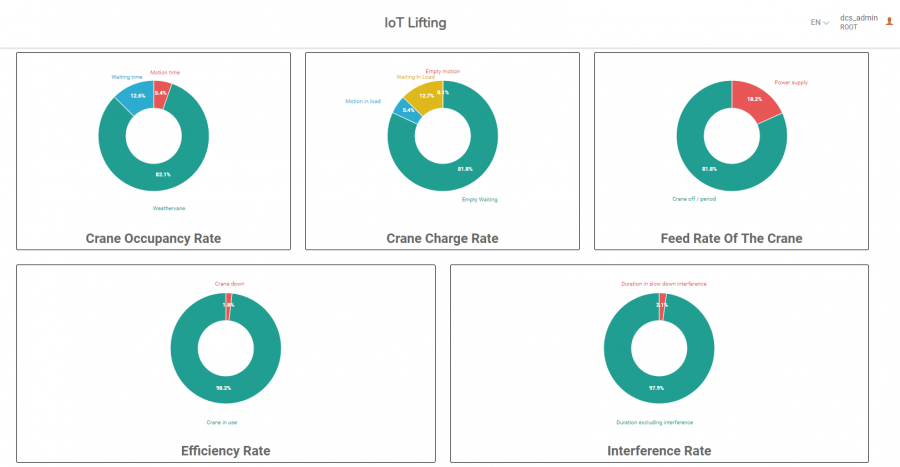

The user can view, analyze, download and share this information. Statistics (customizable) are also generated in the form of circular diagrams (occupancy, load, efficiency, interference rate etc.).

This telematics is not just about accurately tracking remote site productivity and crane activity. This goes far beyond that, by allowing the builder or the hirer, a real evaluation of the productivity according to the concentration of the machines but also an automated management of his fleet of systems. All the systems are mapped, the user has the opportunity to know specific information about them (on which sites his systems are installed, the address of it, on which cranes and their numbers, the version of software, serial numbers of the equipment, which elements of the anti-collision kit are installed, how many cranes are in interference, how many prohibited areas are there ...).

This new tool will be presented at Bauma Munich next April and should be available in 2019 internationally. Indeed, the SIM card that the system is equipped with is universal (compatible in more than 130 countries).

The world is becoming more and more connected every day and new ways of using information are constantly being developed. This new production management tool illustrates the ability of AMCS technologies to keep up with market developments and meet the demand of its customers with innovative technological solutions.

Ultime notizie di OnSite News

Lifting

16/05/2024

Sinoboom marks South American milestone with opening of Brazil subsidiary

Over 100 Brazilian rental company customers attended the con...

Lifting

09/05/2024

Crane Service provider takes delivery of first Tadano AC 7.450-1 all terrain crane in the Czech Republic

Crane Service provider takes delivery of first Tadano AC 7.4...

Components

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...

Components

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

Lifting

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

Earthmoving Machinery

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

Altri International

International

17/05/2024

Volvo CE has taken a 22% ownership stake in VizaLogix

Volvo CE has taken a 22% ownership stake in VizaLogix, a US-...

International

17/05/2024

Manitowoc donates crane simulator to IUOE’s training center in Texas

• Manitowoc has provided cranes and technical support to eve...

International

16/05/2024

Boulard TP banks on Liebherr Crawler Dozers

Once again, this year France was home to the biggest motorcy...

International

16/05/2024

Sinoboom marks South American milestone with opening of Brazil subsidiary

Over 100 Brazilian rental company customers attended the con...

International

15/05/2024

Hiab expands its spare parts offering

Hiab expands its spare parts offering so every customer find...

International

15/05/2024

Second wind farm with Herrenknecht OFD technology

Herrenknecht's Offshore Foundation Drilling (OFD) technology...