Home \ International \ Liebherr "flat-top" crane at work on Mont Blanc

Liebherr "flat-top" crane at work on Mont Blanc

16/02/2023

Pubblicato da Ettore Zanatta

A Liebherr 150 EC-B 8 2flat-top" crane, whose assembly required the use of a helicopter, is an integral part of the project.

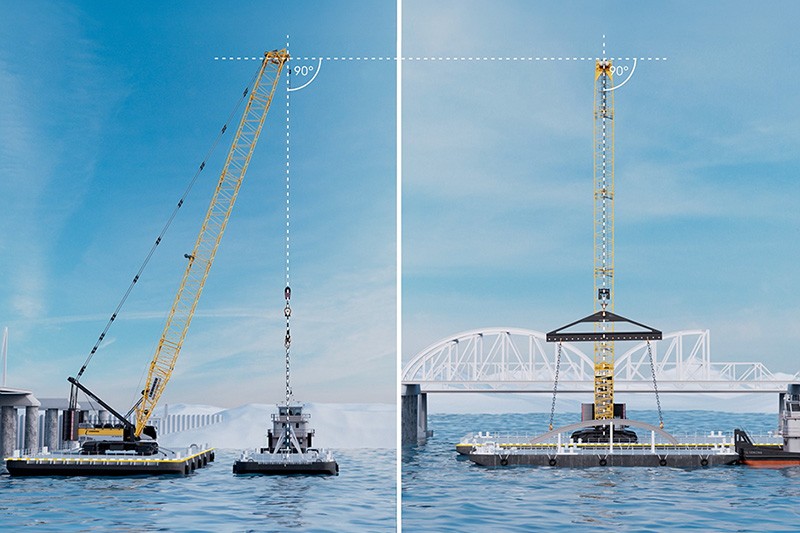

The flat-top crane's tower is in place: a helicopter delivered one tower section after another to the Montenvers mountain station up at an altitude of 1,913 metres, after the foundation anchor was secured to the massif.

Four assembly engineers from Liebherr's partner FT Montage and six flight assistants from Heliswiss International took delivery of the parts from overhead, connected them and worked their way up to a tower height of over 40 metres. A spectacular panorama presents itself: rock faces, trees and ice fields sparkle in the sunshine. But the engineers have little time to appreciate the views from the foot of Mont Blanc, the highest mountain in the Alps and the European Union. The helicopter is on its approach with the crane’s slewing platform.

“Assembly has been a true team effort that wouldn't have been possible without mutual trust,” says Guillaume Riband, Operations Manager France Centre East at Vinci Construction France. “Everyone has pulled together and risen to the challenge as a result.” FT Montage won the "Trophée des Grues á Tour" in the category "Assembly of the Year" due to the complexity and difficulty of the operation. The award is presented annually by the CPMDG (Professional commission for tower crane professions and equipment) from the DLR Federation.

A job like this one with a 150 EC-B 8 in the middle of the Alps isn't something that happens every day. The crane, with a 45-metre jib and a hook height of 42 metres, will support the construction of the new cable car station and the International Glacier and Climate Interpretation Centre until June 2023. The new “Glaciorium” is to become the flagship attraction at Montenvers and will help visitors to understand the phenomena associated with global warming. The Montenvers redevelopment will cost more than 50 million euros and is due to be completed in December 2024. The project was designed to be of high ecological and architectural quality in order to minimise the impact on nature. In terms of energy consumption, waste disposal and visitor awareness, the project fulfils high standards.

One of the biggest challenges the construction company faced was selecting the right crane. Originally, the site required a crane in the 250 metric tonnes range due to the loads that needed to be moved. This value is based on radius (m) and lifting capacity (t) and serves to classify the size of the crane. As such a crane is too heavy for helicopter assembly, Liebherr worked with customers Solumat GAT ( Materials Division, Vinci Group) and CBCE Grenoble (a local construction company that is part of the Vinci Group) to find economic alternatives. Depending on temperature and altitude, the helicopter can move a maximum of 3,800 kilograms.

In the end, Liebherr suggested the use of a 150 EC-B, as its counter jib, which weighs in at 3,600 kilograms, is light enough for the helicopter to manage. Plus, the flat-top crane can be easily dismantled into several individual parts thanks to its flexible design concept. Elements such as the crane’s compact head, slewing platform, cabin and control cabinet can all be quickly reconnected. The site's architects and the construction company also adapted the planning so that the loads to be moved wouldn’t exceed the crane's maximum lifting capacity of eight tonnes. This was in part achieved through the use of lighter concrete elements. For safety reasons, the Montenvers train, which dates back to 1910, was temporarily suspended due to the proximity of its power lines. The retro-style electric rack railway connects Chamonix-Mont-Blanc and Montenvers. It climbs steeply upwards for more than five kilometres and visitors reach the terminus at an altitude of 1,913 metres after approx. 20 minutes.

Thanks to the right choice of crane, good preparation and a well-coordinated team, the assembly on Mont Blanc has gone smoothly. The unusual assembly of the 150 EC-B took around eight hours. During this time, a powerful Kamov KA 32 A11 BC heavy-lift helicopter from Heliswiss International flew back and forth 30 times to deliver all the crane parts and tower system elements. The delivery site needed to be easily accessible for trucks and offer sufficient space. The location chosen was an area in Chamonix on the Arveyron River, about 3.5 kilometres from the Montenvers mountain station. This relatively short distance helped to keep flight times, and therefore refuelling, to a minimum. “Precision planning has been key to this all-round successful assembly,” Guillaume Riband concludes.

This is the second successful helicopter assembly for Heliswiss International and Liebherr. In 2015, they used a helicopter to transport a 150 EC-B 6 flat-top crane onto the Zugspitze to work on the construction of the new Eibsee cable car station. Up at an altitude of 2,975 metres, the crane marked Germany's highest construction site back then. The 150 EC-B 8 won't quite reach such heights in France, but sub-zero temperatures are expected here in the winter months as well. This isn't a problem for Liebherr tower cranes, which are designed for such conditions.

Ultime notizie di Liebherr Italia

Lifting

22/04/2024

Liebherr is part of the largest construction project in Greenland's history

Around 250 kilometres north of the Arctic Circle, Liebherr i...

Lifting

15/04/2024

Liebherr tower cranes renovate bridge in Spain

Two Liebherr 420 EC-H 16 Litronic cranes are secured to the...

Lifting

08/04/2024

150-tonne lifting capacity: Liebherr expands its telescopic crawler crane line-up with the LTR 1150

Liebherr has expanded its range of telescopic crawler cranes...

Lifting

11/03/2024

Expertise and Liebherr power in a two-pack

Liebherr LTM 1650-8.1 and LTM 1450-8.1 from MSG Krandienst a...

Lifting

12/01/2024

Liebherr L1 fast-erecting crane at work inside Passau Cathedral

Liebherr L1 fast-erecting crane at work inside Passau Cathed...

Lifting

09/01/2024

Riga Mainz replaces old railway bridge with Liebherr crawler crane LR 1750/2

Riga Mainz utilized a Liebherr LR 1750/2 crawler crane to re...

Altri International

International

08/05/2024

ESTA Award for Liebherr-Werk Nenzing

Liebherr-Werk Nenzing GmbH won the award in the category "Sa...

International

08/05/2024

Unplug and Play: Introducing Yanmar CE’s All-New Electric Trio

anmar Compact Equipment EMEA proudly unveiled its electric c...

International

07/05/2024

Benninghoven: 100% green hydrogen system for road construction

Benninghoven presentes a new burner generation allows for ev...

International

07/05/2024

JCB adds raptor Tilt-Rotator to Hydradig options list

JCB has unveiled a brand-new tilt rotator designed specifica...

International

06/05/2024

Genie Recognizes Six European and East Dealers with Dealer of the Year Awards

Strong Partnerships and a Commitment to Quality and Customer...

International

06/05/2024

MB Crusher has exhibited its equipments at Intermat 2024

MB Crusher has exhibited for the first time in full the rang...