Home \ International \ Flydeck by Pilosio: true innovation for suspended scaffolding applications

Flydeck by Pilosio: true innovation for suspended scaffolding applications

01/07/2022

Pubblicato da Redazione

Flydeck systema offers significant reduction in set-up time and no need to stop road or railway traffic flow.

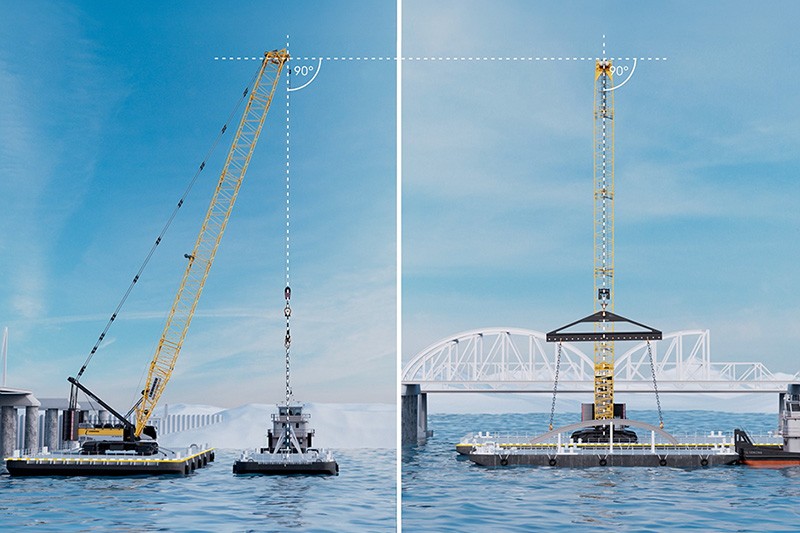

The Flydeck system is a certified system to simplify, speed up and make the assembly of suspended scaffolding and structures safer. It is a perfectly horizontal surface or such to wrap around the architectural shape of the structure to work comfortably on any construction site where suspended scaffolding is needed. In addition, using the Flyrail to set up the Flydeck surface allows the work to become easy and fully safe. With this solution, it is possible to create wraparounds for columns, piles, dosserets and any other element.

The Flydeck surface must be anchored to the back side of the deck (such as roads, highways or railways) without blocking traffic.There are no width, length, or capacity limitations since it is modular and can be combined with beams and scaffolding steel planks of any brand, model, shape, and size. The system consists of 25-cm or 45-cm aluminum, or steel lattice girders connected by patented pins and spring pins. The girders are installed using the FLYRAIL rail that guarantees, in addition to high safety, a significant reduction in assembly and disassembly time for each stage by about one-third compared to traditional systems and about one-half compared to multi-directional scaffolding systems.

The Flydeck system is truly innovative: the FLYRAIL rail supports the cantilevered girders of the Flydeck surface while the operator arranges the surface and anchors it in full safety. The real advantage is the FLyrail, which resolves all those assembly issues that call for the rental of alternative systems that - in addition to being expensive – require stopping roadway or railroad traffic. The Flydeck system can be assembled by accessing it from an abutment or a column without using the by-bridge or negative surface platforms. This solution greatly reduces the assembly and disassembly time of suspended structures by halving their cost and greatly reduces costs in case of rental, halving the storage overall dimensions and costs for handling and transportation.

In addition, 25 cm aluminum or steel girders offer more maneuverability than the 45 cm ones. Joining the beams is very fast and safe thanks to the patented spring pins that simplify assembly and disassembly and ensure perfect co-planarity of the work surface. This system, in addition to significantly increasing operator safety, offers significant time savings during set-up and dismantling, as well as the reduction in purchase, rental, transportation and storage costs, and allows the company not to interfere in any way with normal roadway traffic operation. With the FLYRAIL system, the suspended surface can be easily assembled in several stages whenever the structure being served calls for it.

Ultime notizie di Pilosio

Altri International

International

08/05/2024

ESTA Award for Liebherr-Werk Nenzing

Liebherr-Werk Nenzing GmbH won the award in the category "Sa...

International

08/05/2024

Unplug and Play: Introducing Yanmar CE’s All-New Electric Trio

Yanmar Compact Equipment EMEA proudly unveiled its electric...

International

07/05/2024

Benninghoven: 100% green hydrogen system for road construction

Benninghoven presentes a new burner generation allows for ev...

International

07/05/2024

JCB adds raptor Tilt-Rotator to Hydradig options list

JCB has unveiled a brand-new tilt rotator designed specifica...

International

06/05/2024

Genie Recognizes Six European and East Dealers with Dealer of the Year Awards

Strong Partnerships and a Commitment to Quality and Customer...

International

06/05/2024

MB Crusher has exhibited its equipments at Intermat 2024

MB Crusher has exhibited for the first time in full the rang...