Home \ International \ Walterscheid Powertrain Group at Bauma 2019

Walterscheid Powertrain Group at Bauma 2019

23/04/2019

Pubblicato da Redazione

Walterscheid Powertrain Group highlighted in Hall A3.239 the Mechanics Synergy series of driveshafts of the 3C-10C series, the B3000 series of Double Universal Joints, and the continuously variable travel drive ICVD S1N 370V.

Walterscheid Powertrain Group presented innovative products and technologies at Bauma 2019. Amongst other products and information, Walterscheid Powertrain Group highlighted in Hall A3.239 the Mechanics Synergy series of driveshafts of the 3C-10C series, the B3000 series of Double Universal Joints, and the continuously variable travel drive ICVD S1N 370V.

The innovative Walterscheid Powertrain Group product range particularly focuses on performance, weight reduction and increased efficiency as well as ease of operation with low service and maintenance requirements, thus offering excellent cost-benefit ratios.

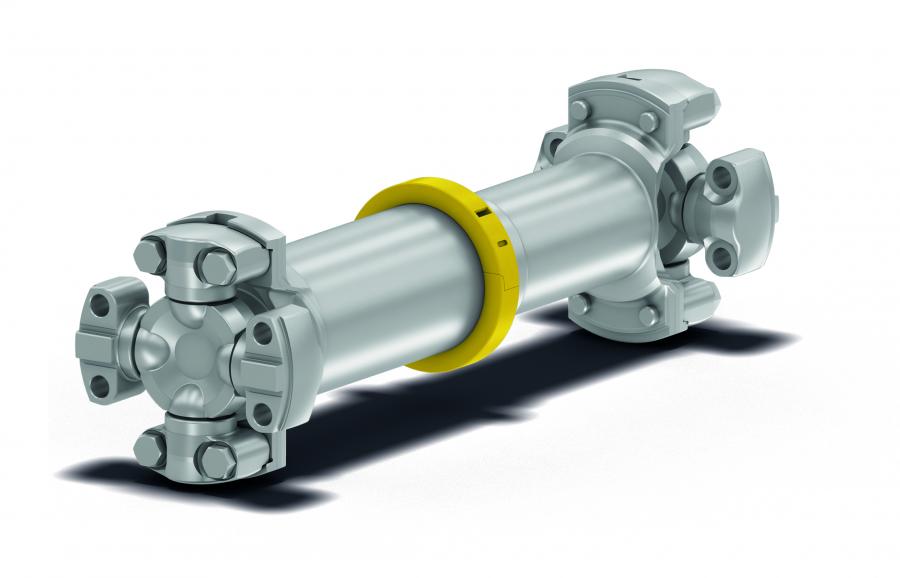

Mechanics Synergy driveshafts

Designed for a broad range of uses and operations in construction, mining, defence and other off-highway markets, Mechanics Synergy is an evolution of existing Walterscheid Powertrain Group product innovations with new features and benefits to offer significant advantages to customers.

The range was developed by linking existing, proven Walterscheid Powertrain Group off-highway technologies, from its market-leading Mechanics® Series U-Joints range, with inverted slip and shaft design expertise. Available in sizes 3C-10C, the product range offers significant advantages and reduces the need for servicing and maintenance and maximises uptime and productivity.

Design characteristics of the Mechanics Synergy series lead to various benefits: The market leading slip section sealing ensures superior product life even in the harshest of off-highway environments. The unique design geometry allows for weight saving, thereby improving vehicle fuel efficiency, and has excellent low wear characteristics to ensure maximum operator comfort throughout the product lifespan. Operators and owners also benefit from the entirely service-free design, saving time and money by not needing to ever grease any shaft components.

Vehicle manufacturers also benefit from the years of product development and selection experience in the Mechanics product range. This includes knowing that the grease used in the product, which is so critical for life, has been carefully selected for the requirements of off-highway vehicles, and is proven in laboratory and field testing.

More torque, same space: New B3000 Double Universal Joints

The Double Universal Joint (DUJ) B3000 series from Walterscheid Powertrain Group allows the transmission of significantly more torque – up to 20 percent – without increasing space requirements. Transmitting higher torque in the same space as the previous B300 series can result in substantial weight savings when new B3000 series DUJs are integrated into an axle, as the axle structure can be smaller and lighter than previously required for the given torque.

Reducing the structural weight makes vehicles more responsive to the operator's inputs for acceleration and deceleration. Whilst vehicle manufacturers aim at increasing the available torque, there are limitations when more torque requires larger and heavier components. This can result in weight increases of both the DUJ and the axle. As the torque capacity of the DUJ B3000 series was increased within the same space requirements, however, there is no need for a larger axle, thus avoiding additional weight and cost.

The increased performance at the same weight offers interesting opportunities to vehicle manufacturers who continuously try to reduce the structural weight of their vehicles. Less weight allows for improved fuel efficiency, thereby reducing the cost of operation. At the same time, reduced emissions improve the environmental performance of the vehicles.

Following Walterscheid Powertrain Group’s strategic commitment to “Differentiation Through Technology” and a multi-year development process, the new DUJ B3000 series were presented at Bauma 2019. The increased performance was achieved through a combination of material selection and optimisation of component geometry, and was supported by extensive laboratory and field testing. The first size, B3310, is now in production for the launch customer's pre-series production model, with the B3320 in an advanced stage of development.

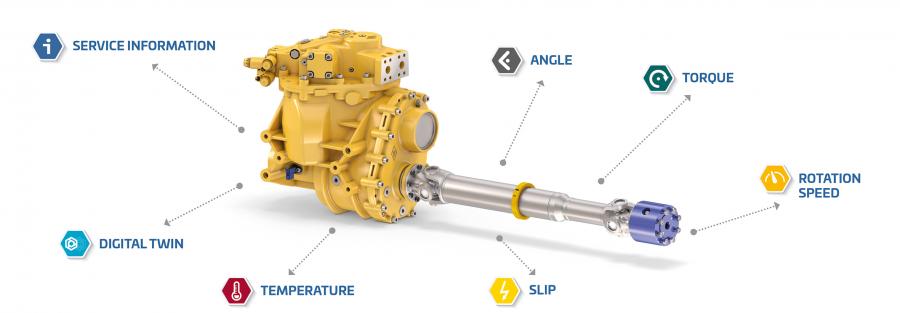

ICVD S1N 370V: Energy-efficient and comfortable

The new continuously variable travel drive ICVD S1N 370V provides convincing answers to growing requirements in terms of tractive force, speed and energy efficiency of agricultural and construction machinery. Tractive force is provided through the entire speed range up to 40 kph without a shifting process or interruption. This ensures high user comfort and also has significant effects with regard to energy efficiency.

That is particularly true for full vehicle power management systems with one motor powering different components. As no friction clutches or additional hydraulic motors are required, this technology also delivers convincing results in terms of reduced drag-torque and costs of the system in comparison to multi-motor concepts.

A standard control component which already is in use in other drives was integrated into the new continuously variable travel drive. This offers various control options and ensures perfect compatibility with available controller and software interfaces. In addition, the use of this high-volume component allows for maximum ruggedness and reliability of the new continuously variable travel drive.

Despite the extremely compact dimensions of hydraulic motor and gearbox, and a weight of approximately 200 kg, the high-performance travel drive offers a convincing power capacity of 130 kW. The ICVD P370 is based on a bent axis motor kit with corresponding swivel mechanism and control unit and was developed for trouble-free application in a wide range of agricultural and construction machinery.

The ICVD P370 was designed in a joint development project by Walterscheid and Danfoss Power Solutions as a key partner, thus allowing for a systematic and holistic approach. Walterscheid Powertrain Group took particular responsibility for construction, manufacturing and test bench trials whilst Danfoss Power Solutions provided technical expertise as well as support for system and component integration especially during the development phase and vehicle testing.

About Walterscheid Powertrain Group

Walterscheid Powertrain Group is a global provider of connected and smart powertrain solutions and complete in-service support for the world’s leading off-highway and industrial equipment manufacturers. The firm continuously develops new technologies and customer solutions which deliver efficiency in the agriculture, construction, mining, utility vehicle and industrial markets and offers through life services for all powertrain products and systems between power source and power applied. With its global platform across 4 continents, Walterscheid Powertrain Group is the technology partner and innovation leader to the global leading OEMs. This together with a comprehensive aftermarket and service offering positions the group for above market long term growth.

Ultime notizie di OnSite News

Components

26/04/2024

SVAB launches the successor to the popoular joystick Grip L8

At this year’s edition of Intermat in Paris on April 24-27,...

Components

25/04/2024

Genuine parts ensure articulated hauler quality and uptime

The importance of good quality, reliable parts when maintain...

Lifting

25/04/2024

Steil takes delivery of new Tadano AC 6.300-1 all terrain crane

Steil takes delivery of new Tadano AC 6.300-1 all terrain cr...

Earthmoving Machinery

23/04/2024

Bauma Innovation Award: Kick-off 2 May 2024

On the occasion of bauma 2025, the leading associations of t...

Lifting

19/04/2024

XCMG unveiled its premium G2 crane brand

G2 Integrates the whole process of product application, main...

Services

18/04/2024

BladeLifter from TII SCHEUERLE is the perfect choice for even the longest rotor blades

The fourth generation SCHEUERLE BladeLifter allows all fleet...

Altri International

International

06/05/2024

Genie Recognizes Six European and East Dealers with Dealer of the Year Awards

Strong Partnerships and a Commitment to Quality and Customer...

International

06/05/2024

MB Crusher has exhibited its equipments at Intermat 2024

MB Crusher has exhibited for the first time in full the rang...

International

03/05/2024

JCB: New factory-fitted machine control solutions launched

JCB and Leica Geosystems, part of Hexagon, today announced t...

International

02/05/2024

Two winning pairs from Magni TH at Intermat 2024

Magni TH has chosen Interma for the unveil of two new telesc...

International

30/04/2024

JCB's new generation backhoes bring greater levels of versatility

JCB unveils a number of key improvements to its backhoe load...

International

29/04/2024

Wirtgen's global market launch: Rock Crusher WRC 240(i)

Rock Crusher WRC 240(i) is the new Wirtgen's specialist for...