Home \ International \ Two winning pairs from Magni TH at Intermat 2024

Two winning pairs from Magni TH at Intermat 2024

02/05/2024

Pubblicato da Ettore Zanatta

Magni TH has chosen Interma for the unveil of two new telescopic handlers and two innovative attachments.

Intermat is one of the top construction machinery events. Magni TH has chosen this international stage for the unveil of two new telescopic handlers and two innovative attachments.

With capacity of 3 tonnes (6613 lbs) and lifting height of 5.8 metres (19 ft), the new TH 3.6 combines small size with impressive performance. In fact, the most compact fixed telescopic handler in the TH range, intended for the construction and logistics sectors and soon also for agriculture, is able to lift its maximum load to a height of 5.4 metres (17.7 ft), 2,500 kg (5511 lbs) to the maximum height and 1,100 kg (2425 lbs) to a horizontal reach of more than 3 metres (10 feet). Its low-level design makes it ideal for tight spaces, while retaining optimal ground clearance for uneven terrains. These characteristics, together with a Deutz Stage V engine of 55 kW (75 hp) give it a top speed of 35 km/h (21 mph). The four-wheel drive and steering, with hydrostatic transmission, provide superlative stability and manoeuvrability with 3 steering modes: front, concentric and crab. With the launch of the TH 3.6 Magni also presents the new compact cab, which maintains the same development approach as its predecessor in the TH range together with a new dashboard that optimises the user experience through the ergonomic placing of the main controls. It also features USB ports (3.0 and c-type) for charging electronic devices and a handy cup holder. The new cab’s standard outfit is completed by the air-suspended seat, adjustable steering column, heating and radio. Consulted via the 7" touch screen, the MCTS (Magni Combi Touch System) on-board software provides

complete control of the machine with icon-based navigation. From the main menu, the operator can access the themed screens with the various functions, including load charts. Unlike competitor models on the market, which have the usual load cell systems, the TH 3.6 is the only machine equipped with a more sophisticated, precise tipping protection mechanism to maximise performance and safety, in line with the entire TH range. This is the LMI (Load Moment Indicator), which enables constant monitoring of the machine’s movements to prevent any kind of overload.

Magni launches three models derived from the market’s best-selling rotating telescopic handlers, the RTH 6.22, 6.26 and 6.31, all equipped with elevating cab. This feature is designed to optimise work in conditions that demand greater visibility and to guarantee the very best comfort level by providing the operator with an ergonomic position, especially when handling delicate loads or using specialist attachments. In these situations, greater visibility means safe, effective movements in even the most complex procedures, such as use of the tree cutting and log handling attachment. The hydraulic mobile support is able to raise the cab to a height of 1.5 metres (5 ft) and tilt it between 0° and +16° for optimal control in conditions where movements must be exceptionally precise.

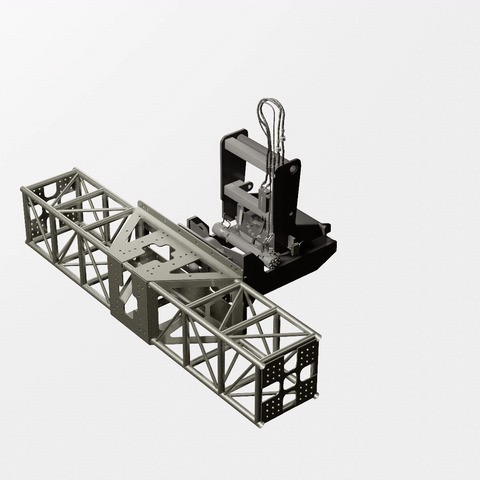

At the Paris show, Magni also revealed two new attachments for the RTH and TH ranges: the 3D-Film handler and the 5T tilting rotating forks. Intended for the movie industry, the 3D-Film handler has a surface fitted to support equipment such as LED light panels or floodlights used during filming in the studio or on location. With a capacity of 2.5 tonnes (5511 lbs) and continuous rotation through 360°, it provides unbeatable manoeuvrability and versatility to offer the optimal response to this specific sector’s needs. The tilting rotating forks, on the other hand, are designed for handling bulky materials in tight spaces. Unlike standard forks, they rotate and swivel to optimise movement of the weight during loading and unloading. They deliver frontal lifting capacity of up to 5 tonnes (11,000 lbs), rotated load capacity of up to 2.5 tonnes (5511 lbs), continuous rotation through 360° and positive tilting up to 70°. With targeted solutions for the demands of a constantly growing sector, Magni TH further extends its range of products to continue its expansion at the global level.

Ultime notizie di Magni Telescopic Handlers

Lifting

11/03/2024

The latest from Magni at Intermat 2024

From 24 to 27 April, Magni will be launching the new TH 3.6...

Lifting

25/01/2024

The new Magni TH 3.6 fixed telescopic handler

Magni will make its official debut on the small fixed telesc...

Lifting

28/06/2022

Magni TH at the service of Italmontaggi

Italmontaggi chooses Magni for the construction of a new str...

Lifting

24/06/2022

RTH 6.35 telescopic handler dealing with a seismosaur

To celebrate its 30th anniversary, the ‘Dinozoo’ prehistoric...

10/12/2020

Magni TH: partnership with Bobcat!

Magni TH will supply Bobcat with rotating telehandlers rangi...

13/03/2019

Magni new headquarters: 2020 inauguration!

A project featuring the Castelfranco Emilia-based company in...

Altri International

International

17/05/2024

Volvo CE has taken a 22% ownership stake in VizaLogix

Volvo CE has taken a 22% ownership stake in VizaLogix, a US-...

International

17/05/2024

Manitowoc donates crane simulator to IUOE’s training center in Texas

• Manitowoc has provided cranes and technical support to eve...

International

16/05/2024

Boulard TP banks on Liebherr Crawler Dozers

Once again, this year France was home to the biggest motorcy...

International

16/05/2024

Sinoboom marks South American milestone with opening of Brazil subsidiary

Over 100 Brazilian rental company customers attended the con...

International

15/05/2024

Hiab expands its spare parts offering

Hiab expands its spare parts offering so every customer find...

International

15/05/2024

Second wind farm with Herrenknecht OFD technology

Herrenknecht's Offshore Foundation Drilling (OFD) technology...